Innovative Design: The Future of Plastic Food Container Moulds

Plastic food container moulds are fundamental tools in the manufacturing process of plastic containers widely used for food storage, packaging, and transportation. These moulds determine the quality, shape, durability, and safety of the containers that millions of consumers rely on daily. Understanding the characteristics and performance of plastic food container moulds is crucial for manufacturers aiming to produce containers that meet strict food safety standards while maintaining efficient production and high product quality.

Plastic food container moulds are precision-engineered tools designed to shape molten plastic into various container forms through injection molding or thermoforming processes. The mould consists of a cavity that defines the shape and dimensions of the container, including features such as lids, walls, and locking mechanisms when applicable.

The materials used for these moulds are typically hardened steel or high-grade aluminum, chosen for their strength, resistance to wear, and ability to withstand repeated thermal cycling during manufacturing. The mould’s design directly impacts the container’s structural integrity, appearance, and functional properties, such as airtight sealing and ease of use.

The precision of a plastic food container mould is paramount. Containers must meet exact dimensional requirements to ensure proper sealing, stacking, and compatibility with lids or other accessories. The mould cavity is carefully designed using advanced CAD (Computer-Aided Design) and CAM (Computer-Aided Manufacturing) systems to achieve tight tolerances.

Accurate moulds reduce defects such as warping, flashing, or incomplete filling, which can compromise the container’s usability and food safety.

Mould materials are selected to balance durability and cost-efficiency. Hardened steel moulds offer superior longevity and maintain dimensional stability over millions of production cycles. Aluminum moulds, although less durable, provide faster heat dissipation and are often used for prototyping or limited production runs.

Surface treatments like nitriding or chrome plating are applied to steel moulds to enhance wear resistance and reduce friction between the mould and the plastic, improving the surface finish of the containers and extending mould life.

https://www.food-container-mold.com/product/disposable-plastic-square-food-container-moulds/square-product-mold.html

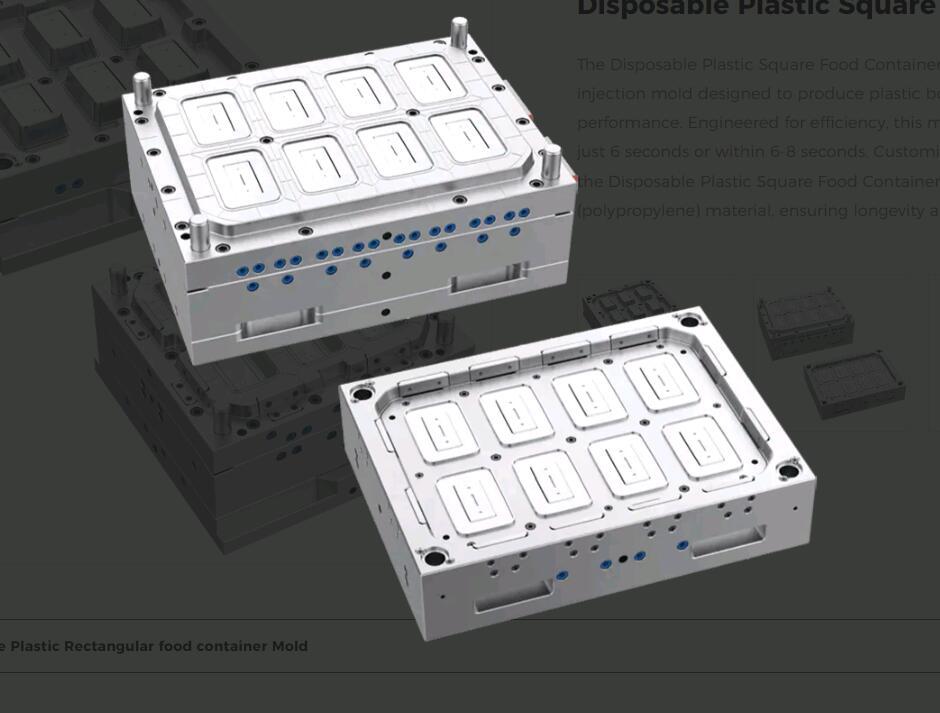

The Disposable Plastic Square Food Container Mold is a high-precision plastic injection mold designed to produce plastic boxes and lids with excellent sealing performance. Engineered for efficiency, this mold ensures a swift molding cycle of just 6 seconds or within 6-8 seconds. Customizable to meet specific requirements, the Disposable Plastic Square Food Container Mold is made from durable PP (polypropylene) material, ensuring longevity and reliability.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Игры

- Gardening

- Health

- Главная

- Literature

- Music

- Networking

- Другое

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness