Precision Engineering: The Role of Medical Syringe Moulds in Healthcare

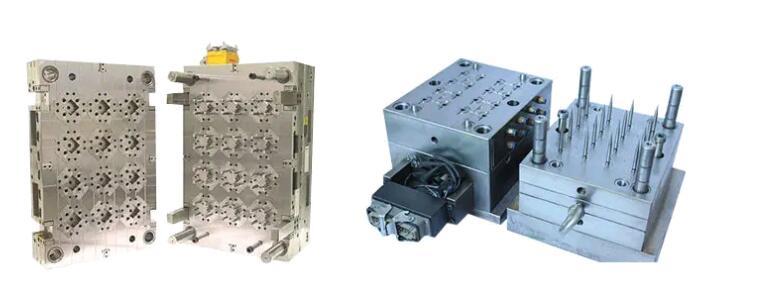

Medical syringe moulds are critical tools in the manufacturing process of disposable syringes, which are widely used in healthcare settings worldwide. These moulds are precision-engineered components designed to produce high-quality syringe barrels and plungers through injection molding of medical-grade plastics such as polypropylene and polyethylene. The performance and characteristics of medical syringe moulds directly impact the accuracy, safety, and reliability of the syringes produced, making their design and functionality essential for the medical device industry.

Medical syringe moulds require extremely tight dimensional tolerances due to the functional demands of syringes. The barrel and plunger must fit together perfectly to ensure smooth movement without leakage, while maintaining airtight seals to prevent contamination. Mould cavities are manufactured with micron-level precision to achieve these exact specifications, ensuring consistent syringe quality.

The mould design also accommodates features such as graduation markings on the barrel and flange geometry for user grip, which are essential for proper dosage measurement and handling.

The mould materials are typically high-grade steel or stainless steel, which provide durability and corrosion resistance during repeated injection cycles. Additionally, the mould’s surface finish must be smooth and defect-free to ensure the syringes have a clean, medical-grade appearance and do not harbor contaminants.

Surface treatments such as polishing or coating are applied to mould cavities to enhance product release and reduce wear, thereby extending mould lifespan.

To meet the high demand for disposable syringes, medical syringe moulds are often designed with multiple cavities, allowing simultaneous production of several syringe components in one molding cycle. Multi-cavity moulds significantly improve production efficiency and reduce manufacturing costs.

https://www.ysmou.com/product/medicine-mould/injection-medical-syringe-mould.html

Core slider: Luer interface slider system

Gate type: hot runner point gate

Product plastic: TPE or medical PVC (if using PVC, I

We do not recommend the use of thermal guides)

Cavity Core Polishing: Mirror Polishing

Needle plug plug mold structure: using the insert method to make it set

On the mold base, the same parts in the mold can be mutually

Changed.

Syringe tight plug die life: at least 5 million mode

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Games

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Other

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness