Key Factors to Consider When Using WTB Wire to Board Connector

As electronic devices continue to shrink in size while expanding in functionality, engineers face a growing challenge: how to maintain reliable electrical connections in increasingly compact spaces. In these conditions, selecting the right WTB Wire to Board Connector becomes critical—not only to meet electrical performance criteria but also to ensure mechanical fit, assembly ease, and long-term reliability within spatial limitations. Whether it’s a wearable device, a compact drone, or an IoT sensor module, the need for an efficient connector solution in tight installation areas is more pressing than ever.

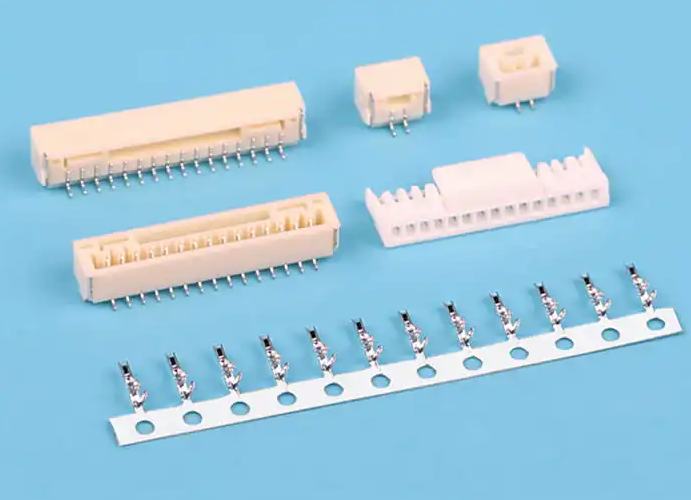

The WTB Wire to Board Connector is widely used in various industries due to its straightforward assembly and strong electrical performance. It bridges discrete wires to a printed circuit board (PCB) and supports a broad range of applications, from home appliances and automotive dashboards to medical instruments and consumer gadgets. However, in space-constrained environments, not all WTB connectors are suitable. Designers must carefully evaluate several physical and mechanical attributes to ensure optimal fit and function.

One of the first considerations is connector profile height. Low-profile WTB connectors are specifically engineered to minimize vertical space usage, which is essential in applications where components are stacked or enclosed in slim housings. Selecting a low-profile variant can prevent mechanical interference and help maintain airflow or thermal performance in tightly packed systems. Some manufacturers offer ultra-slim versions with a mating height as low as 1.0 mm, specifically intended for compact PCB layouts.

Pitch size—the distance between adjacent contacts—is another critical factor. In tight spaces, smaller pitch connectors (e.g., 0.8 mm, 1.0 mm, or 1.25 mm) are generally preferred because they allow for higher pin densities in a smaller footprint. However, designers must balance this with current-carrying capacity and ease of assembly. A smaller pitch often means more delicate handling requirements, and may not support the same current levels as larger pitch designs.

Cable routing also plays a major role in connector selection. Many WTB Wire to Board Connectors come with right-angle or vertical entry configurations. In space-constrained setups, a right-angle connector may allow wires to exit the board in parallel, conserving vertical space and simplifying enclosure design. On the other hand, vertical types might be more suitable when board stacking is involved or when routing cables directly upward is more efficient.

Locking mechanisms and mating force should also be evaluated. In a confined space, applying high insertion force or using bulky locking latches may not be practical. Therefore, choosing a connector with an easy and secure mating feature, such as a friction lock or low-insertion-force terminal, can improve both manufacturability and field serviceability.

Thermal and environmental constraints must also be considered. If the limited space contributes to poor ventilation, connectors made from heat-resistant materials are preferred to avoid degradation over time. In harsh environments, sealed WTB Wire to Board Connectors with moisture or dust resistance may be required even in small form factors.

In summary, choosing the right WTB Wire to Board Connector for space-limited applications requires careful attention to multiple design parameters, including profile height, pitch size, mounting orientation, and mechanical locking features. An optimized connector choice not only ensures reliable electrical performance but also contributes to a more compact, efficient, and serviceable final product.

1、CKT: 2Pin to 25Pin

2、Current rating: 0.5A AC/DC

3、Voltage rating(max): 30V, AC/DC

4、Working Temperature: -25°C~+85C,

(Including temperature rise in applying electrical current)

5、Contact resistance: Initial value s20mΩ

After environmental testing≤40mΩ

6、Insulation resistance: 2100MΩ

7、Withstand voltage: 200VAC(rms)

8、Applicable wire: AWG #32 to #28

9、Applicable PCB board thickness: 1.6mm to 2.0mm

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Jocuri

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Alte

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness