What Makes Hot Forging Machine Tools Essential in Metal Forming?

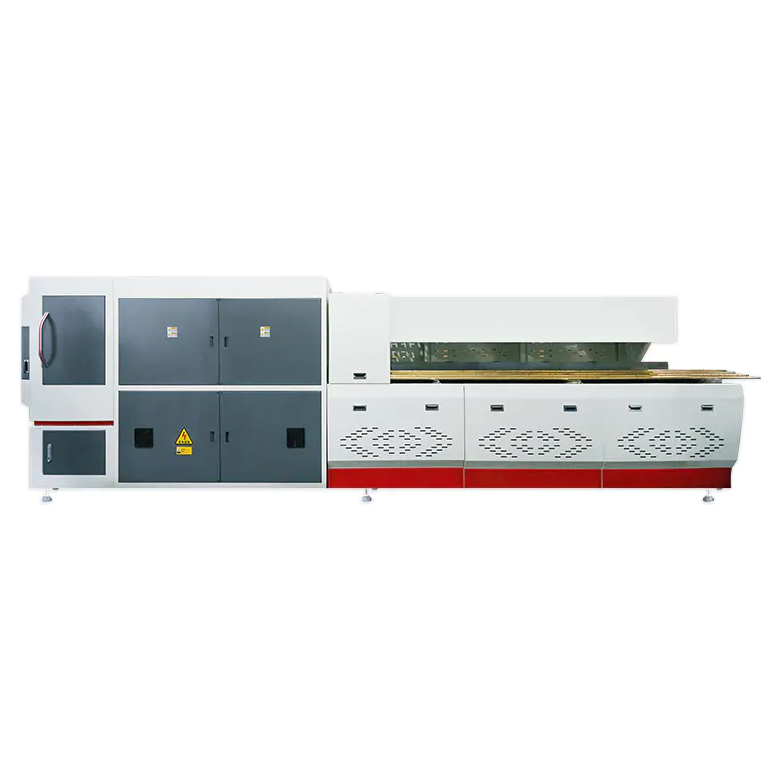

In the field of metal forming, hot forging machine tools play a vital role in producing components with reliable mechanical properties and desired shapes. These machines are designed to work with heated metals, making them easier to deform and mold into various forms required by automotive, aerospace, construction, and industrial sectors. Understanding the specific features of these tools can help industries select the right equipment for their production requirements.

One notable feature of hot forging machine tools is their ability to operate at elevated temperatures. This characteristic allows metals such as steel, aluminum, and copper alloys to become malleable, reducing resistance during deformation. The forging process enhances the internal structure of the material, often leading to improved strength and structural integrity after shaping.

Another important feature lies in the machine’s control systems. Modern hot forging tools are equipped with advanced hydraulic or mechanical systems, providing stable force distribution throughout the forging cycle. This feature contributes to the consistency of the end products’ dimensions and surface finishes. Additionally, programmable control panels allow operators to adjust parameters such as pressure, speed, and stroke length to suit different workpiece sizes and material types.

Durability is also considered in the construction of hot forging machine tools. Manufacturers typically select materials and components that can withstand prolonged exposure to high temperatures and continuous mechanical stress. This ensures that the machines maintain their operational stability during demanding production cycles.

Flexibility is another valued aspect of these machines. Many hot forging machine tools are designed to handle a variety of dies and tooling configurations. This allows manufacturers to switch between different part shapes and production demands without requiring extensive modifications. The capability to adapt tooling setups helps optimize efficiency and reduce downtime during transitions.

Energy efficiency has also become an important focus in the development of forging machinery. Many current models incorporate energy-saving hydraulic systems and intelligent temperature management features. These elements help regulate heat generation and power usage, aligning with industry efforts to reduce operational costs and environmental impact.

Safety is a priority in the design of hot forging machine tools. Protective enclosures, automated controls, and emergency stop systems are commonly integrated to safeguard operators and maintain secure working conditions. These features minimize the risk of accidents in high-temperature, high-pressure environments.

In summary, hot forging machine tools are distinguished by their high-temperature operational capacity, stable control systems, material durability, flexibility in tooling, energy-conscious design, and safety measures. These combined features support consistent and efficient production in industries that require precision-formed metal components. Understanding these characteristics allows businesses to choose equipment that meets both their technical specifications and operational priorities.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Juegos

- Gardening

- Health

- Inicio

- Literature

- Music

- Networking

- Otro

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness