Enhancing Efficiency with Deep Hole Drilling Technologies

Deep hole drilling tools play a critical role in the manufacturing processes of various industries, including aerospace, automotive, and energy. These tools are specifically designed to create holes with high depth-to-diameter ratios, often beyond what conventional drilling methods can handle. Unlike standard cutting tools, deep hole drilling instruments are engineered to maintain straightness and stability over extended drilling lengths, ensuring consistent quality throughout the process.

The structure of a deep hole drilling system typically includes specialized bits, guide sleeves, and coolant delivery systems. Each component contributes to the precise removal of material and effective chip evacuation, which is essential when dealing with deep cavities. Without proper chip control, the risk of tool breakage and poor surface finish increases significantly.

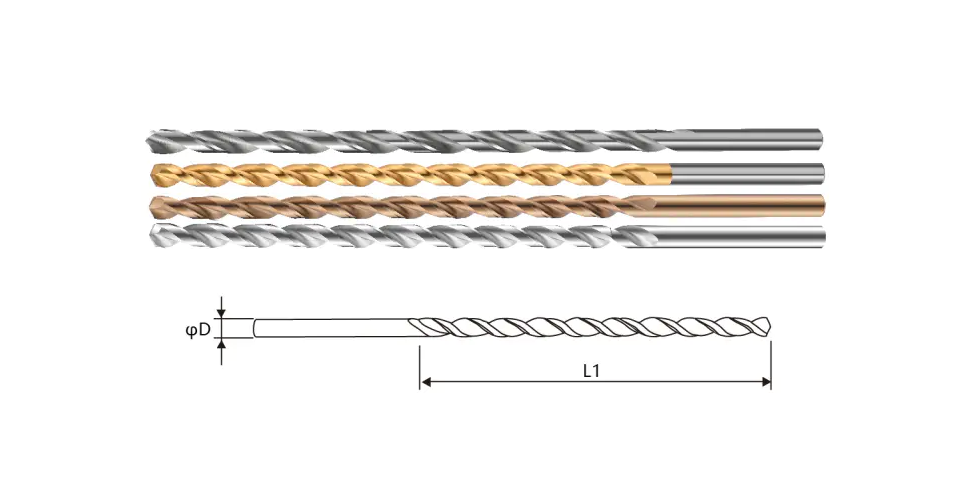

Modern tools used for this purpose often incorporate internal coolant channels. This design allows high-pressure fluid to flush chips away from the cutting edge while cooling both the tool and the workpiece. Such features not only extend the lifespan of the tool but also support smoother drilling operations. Additionally, tool materials and coatings are selected for their ability to withstand high temperatures and friction, which are common in deep hole environments.

Various types of deep hole drilling methods are supported by these tools, including BTA (Boring and Trepanning Association) drilling and gun drilling. Each method offers specific advantages depending on hole size, depth, and workpiece material. Choosing the right tool configuration is essential for achieving dimensional accuracy and reducing production delays.

Continuous developments in tool geometry and material science have contributed to better performance in demanding applications. Although no universal tool suits every situation, manufacturers benefit from a wide range of options tailored for unique drilling needs. With proper selection and maintenance, these tools can deliver dependable results even in tough operating conditions.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Jogos

- Gardening

- Health

- Início

- Literature

- Music

- Networking

- Outro

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness