Meeting Industrial Demands with Spring Forming Machines

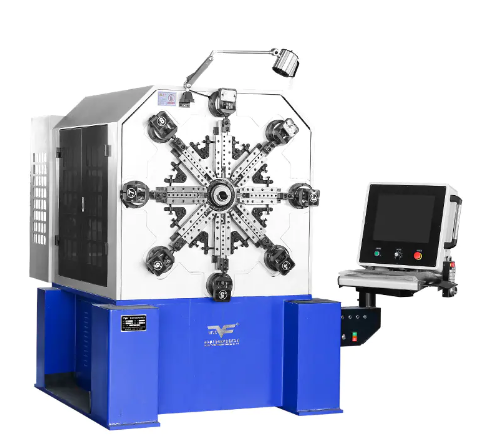

Spring forming machines support a wide range of manufacturing tasks by enabling precise shaping of wire into springs and custom forms. They are essential in sectors that require consistent, repeatable mechanical parts, such as home appliances, industrial tools, and medical devices. The functionality and adaptability of these machines allow for rapid production while maintaining a controlled process environment.

At the heart of the machine is a system designed to feed wire with consistency and accuracy. Driven by programmable commands, the machine can coil and shape the material through coordinated movements. These are often governed by servo motors that respond to digital instructions, resulting in tightly controlled spring dimensions. Such functionality reduces variation between units, even over long production runs.

Modern spring forming machines are engineered to manage different wire diameters and materials. By adjusting tension, speed, and feed angles, operators can shift quickly between production batches with minimal setup time. This flexibility is particularly useful in custom fabrication, where product specifications may change frequently. Wire guides, forming tools, and cutting mechanisms are designed for quick replacement or reconfiguration to reduce transition time.

Another advantage lies in monitoring and error detection. Through integrated sensors and programmable alerts, the machine can detect deviations in spring length, coil spacing, or diameter. This ensures that substandard components are flagged immediately, reducing the risk of defective parts reaching the next stage of assembly.

Some models also feature software integration for production tracking. Operators can monitor usage patterns, predict maintenance needs, and log data for quality audits. This supports both short-term efficiency and long-term operational planning.

Training for spring forming machine operation includes both mechanical understanding and software use. While the interface is designed to be intuitive, understanding wire behavior and tension dynamics is crucial for producing precise parts. Skilled technicians contribute significantly to the machine’s performance by making on-the-fly adjustments and identifying opportunities for efficiency.

By combining mechanical engineering with smart programming, spring forming machines offer a reliable path to consistent part production. Their use in various industries continues to expand as manufacturers look for dependable tools to match growing demand and varied design challenges.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Игры

- Gardening

- Health

- Главная

- Literature

- Music

- Networking

- Другое

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness