Transforming Workshops with Computer-Controlled Precision

In today's production landscape, automatic CNC machines have reshaped how manufacturers handle precision tasks. The fusion of digital technology with mechanical function allows these machines to execute tasks with controlled motion and repeatability. Operating based on coded instructions, they eliminate much of the variability found in manual machining.

CNC stands for computer numerical control, referring to the system that dictates the movements and actions of the machine. Whether shaping metal, cutting plastics, or engraving wood, the process is managed through software that defines tool paths, speeds, and sequences. This structured approach offers advantages in terms of consistency and time management.

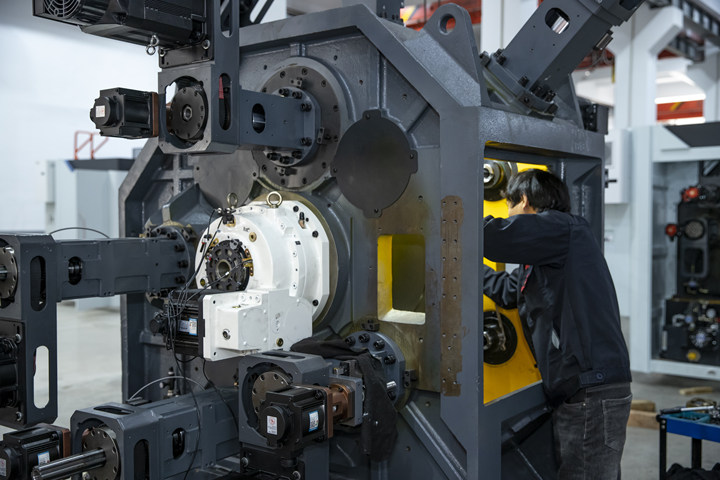

A major aspect of automatic CNC machines is their versatility. A single unit can perform drilling, milling, turning, or cutting, depending on the setup. Changing from one operation to another requires minimal downtime, especially with automatic tool changers and preset configurations. This makes it easier to produce a wide variety of parts without needing multiple machines.

Maintenance and calibration also play an essential role in sustaining the accuracy of CNC systems. Modern versions often include self-diagnostic features that alert operators to inconsistencies or potential failures. This proactive approach reduces unexpected breakdowns and helps schedule service without interrupting the workflow significantly.

The programming side of CNC operation demands a blend of technical understanding and design thinking. Operators often work with CAD (computer-aided design) models that are converted into CAM (computer-aided manufacturing) instructions. This digital pipeline allows for efficient transitions from concept to final product, making the entire process smoother.

Despite automation, skilled human oversight remains important. Setup, programming, and supervision ensure the machine delivers results that match specifications. Teams that understand both the theoretical and hands-on elements can take full advantage of what CNC machines offer.

The influence of automatic CNC machines reaches beyond industrial facilities. Small workshops and educational institutions are also adopting compact versions to train future professionals. As accessibility improves, the technology is likely to become even more widespread across various sectors of production and innovation.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Oyunlar

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Other

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness