Global Mobile Satellite Services Market Projected to Strengthen in Value and Scale by 2029

Grab 20% Off With Code ONLINE20 On Global market Reports – Evaluate Global Trends, Market Risks, and Competitive Intelligence

What Is the Predicted Market Size and CAGR of the Mobile Satellite Services Market by the End of the 2029?

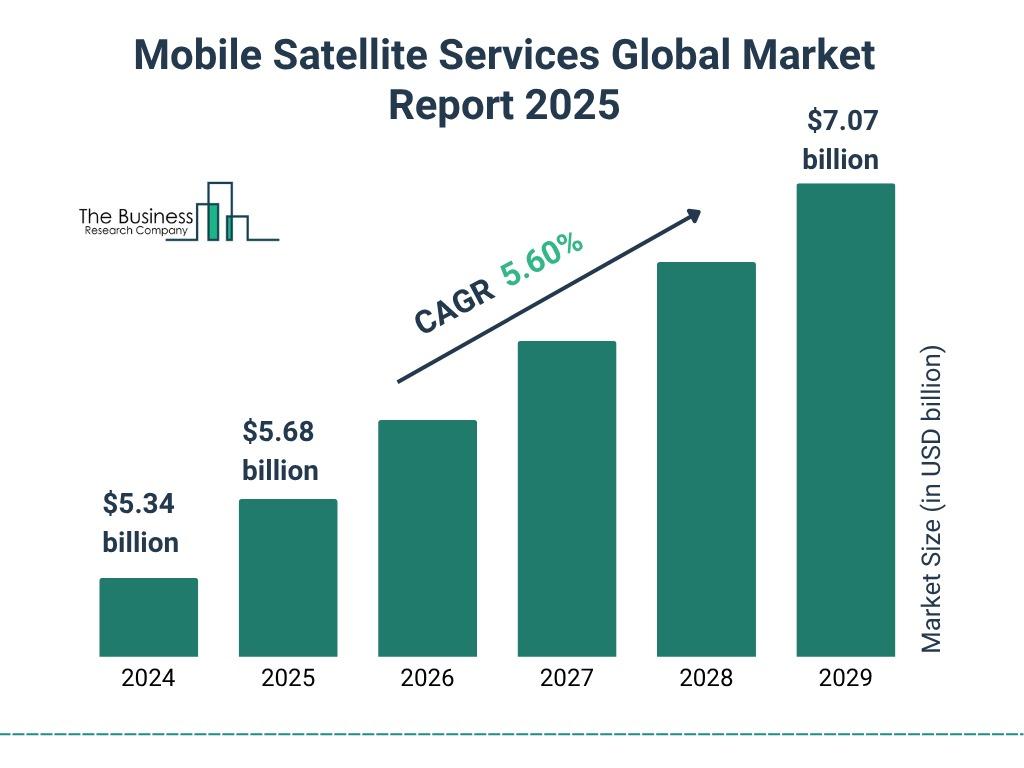

The mobile satellite services market size has grown strongly in recent years. It will grow from $5.34 billion in 2024 to $5.68 billion in 2025 at a compound annual growth rate (CAGR) of 6.4%. The growth in the historic period can be attributed to emergence of global connectivity needs, increased military and defense applications, expansion of broadcasting and media, enterprise connectivity, telecommunications backhaul.

The mobile satellite services market size is expected to see strong growth in the next few years. It will grow to $7.07 billion in 2029 at a compound annual growth rate (CAGR) of 5.6%. The growth in the forecast period can be attributed to emerging market growth, commercial space activities, smart transportation, increased agriculture and precision farming, adoption of smart transportation. Major trends in the forecast period include integration with 5G networks, rapid expansion of IoT connectivity, increasing demand for broadband connectivity, enhanced disaster response and public safety solutions, diversification of service offerings.

Get your free report sample today:

Mobile Satellite Services Market Size and Growth Report 2025 Sample (https://www.thebusinessresearchcompany.com/sample.aspx?id=14143&type=smp)

What Are the Significant Market Forces Driving the Mobile Satellite Services Market Performance?

The expansion of oil and gas exploration is expected to propel the growth of the mobile satellite services market going forward. Oil and gas exploration refers to the process of searching for underground or underwater reservoirs of oil and natural gas deposits. It is rising due to economic, technological, and geopolitical factors to meet global energy needs. Mobile satellite services are used in oil and gas exploration activities to offer dependable communication, data transmission, logistics assistance, and environmental monitoring in remote and challenging environments. For instance, in March 2024, according to the Energy Information Administration, a U.S-based government agency U.S. crude oil production grew by 9% in 2023 compared to 2022, reaching a record 12.9 million barrels per day. This increase has driven higher crude oil exports, despite U.S. refineries continuing to be optimized for processing heavier crude oils. Therefore, the expansion of oil and gas exploration is driving the growth of the mobile satellite services market.

Which Segments Are Likely to Shape the Future Outlook of the Mobile Satellite Services Market?

The mobile satellite servicesmarket covered in this report is segmented –

1) By Service: Voice, Data

2) By Application: Land Mobile Satellite Service, Aeronautical Mobile Satellite Service, Maritime Mobile Satellite Service

3) By Industry: Oil And gas, Media And Entertainment, Transportation, Aviation, Defense, Automative, Government, Other Industries

Subsegments:

1) By Voice: Satellite Phone Services, Push-To-Talk Services

2) By Data: Internet Access Services, Remote Monitoring And Control Services

Which Future-Ready Trends Are Expected to Influence the Mobile Satellite Services Market?

Major companies operating in the mobile satellite service industry are adopting a strategic partnership approach to provide resilient and reliable connectivity, particularly in remote and rural areas where terrestrial infrastructure is insufficient. Strategic partnerships refer to a process in which companies leverage each other's strengths and resources to achieve mutual benefits and success. For instance, in June 2023, Spark New Zealand, a New Zealand-based telecommunications company, partnered with Lynk Global., a US-based developer of satellite-to-mobile-phone satellite constellations. With this partnership, they aim to launch a satellite-to-mobile service, aiming to enhance connectivity for its customers, address key challenges, capitalize on emerging opportunities, and position themselves as a leader in innovative connectivity solutions for the New Zealand market.

Which Major Organizations Influence the Direction of the Mobile Satellite Services Market?

Major companies operating in the mobile satellite services market are Ericsson AB, Telstra Corporation Limited, Singapore Telecommunications Limited., Viasat Inc., Intelsat SA, SES S.A., EchoStar Corporation, Hughes Network Systems, AI Yah Satellite Communications company P.J.S.C, Inmarsat plc, Eutelsat Communications S.A., Telesat Canada, Iridium Communications Inc., Telespazio S.p.A., Comtech Telecommunications Corporation, Orbcomm Inc., Encompass Digital Media Inc., Speedcast International Limited, Globecast Asia Pte Ltd, Gilat Satellite Networks Ltd., Globalstar Inc., Avanti Communications Group plc, Ligado Networks LLC, Russian Satellite Communications Company (RSCC), MTN Satellite Communications Inc.

Get the detailed mobile satellite services market report today

https://www.thebusinessresearchcompany.com/report/mobile-satellite-services-global-market-report (https://www.thebusinessresearchcompany.com/report/mobile-satellite-services-global-market-report)

Which Region Holds the Largest Share of the Mobile Satellite Services Market?

North America was the largest region in the Mobile Satellite Service market in 2024. North America is expected to be the fastest-growing region in the forecast period. The regions covered in the mobile satellite services market report are Asia-Pacific, Western Europe, Eastern Europe, North America, South America, Middle East, Africa.

#Contact Us:#

The Business Research Company: Market Research Reports (https://thebusinessresearchcompany.com/)

Americas +1 310-496-7795

Asia +44 7882 955267 & +91 8897263534

Europe +44 7882 955267

Email: info@tbrc.info (mailto:info@tbrc.info)

#Follow Us On:#

LinkedIn: The Business Research Company | LinkedIn (https://in.linkedin.com/company/the-business-research-company)

Grab 20% Off With Code ONLINE20 On Global market Reports – Evaluate Global Trends, Market Risks, and Competitive Intelligence

What Is the Predicted Market Size and CAGR of the Mobile Satellite Services Market by the End of the 2029?

The mobile satellite services market size has grown strongly in recent years. It will grow from $5.34 billion in 2024 to $5.68 billion in 2025 at a compound annual growth rate (CAGR) of 6.4%. The growth in the historic period can be attributed to emergence of global connectivity needs, increased military and defense applications, expansion of broadcasting and media, enterprise connectivity, telecommunications backhaul.

The mobile satellite services market size is expected to see strong growth in the next few years. It will grow to $7.07 billion in 2029 at a compound annual growth rate (CAGR) of 5.6%. The growth in the forecast period can be attributed to emerging market growth, commercial space activities, smart transportation, increased agriculture and precision farming, adoption of smart transportation. Major trends in the forecast period include integration with 5G networks, rapid expansion of IoT connectivity, increasing demand for broadband connectivity, enhanced disaster response and public safety solutions, diversification of service offerings.

Get your free report sample today:

Mobile Satellite Services Market Size and Growth Report 2025 Sample (https://www.thebusinessresearchcompany.com/sample.aspx?id=14143&type=smp)

What Are the Significant Market Forces Driving the Mobile Satellite Services Market Performance?

The expansion of oil and gas exploration is expected to propel the growth of the mobile satellite services market going forward. Oil and gas exploration refers to the process of searching for underground or underwater reservoirs of oil and natural gas deposits. It is rising due to economic, technological, and geopolitical factors to meet global energy needs. Mobile satellite services are used in oil and gas exploration activities to offer dependable communication, data transmission, logistics assistance, and environmental monitoring in remote and challenging environments. For instance, in March 2024, according to the Energy Information Administration, a U.S-based government agency U.S. crude oil production grew by 9% in 2023 compared to 2022, reaching a record 12.9 million barrels per day. This increase has driven higher crude oil exports, despite U.S. refineries continuing to be optimized for processing heavier crude oils. Therefore, the expansion of oil and gas exploration is driving the growth of the mobile satellite services market.

Which Segments Are Likely to Shape the Future Outlook of the Mobile Satellite Services Market?

The mobile satellite servicesmarket covered in this report is segmented –

1) By Service: Voice, Data

2) By Application: Land Mobile Satellite Service, Aeronautical Mobile Satellite Service, Maritime Mobile Satellite Service

3) By Industry: Oil And gas, Media And Entertainment, Transportation, Aviation, Defense, Automative, Government, Other Industries

Subsegments:

1) By Voice: Satellite Phone Services, Push-To-Talk Services

2) By Data: Internet Access Services, Remote Monitoring And Control Services

Which Future-Ready Trends Are Expected to Influence the Mobile Satellite Services Market?

Major companies operating in the mobile satellite service industry are adopting a strategic partnership approach to provide resilient and reliable connectivity, particularly in remote and rural areas where terrestrial infrastructure is insufficient. Strategic partnerships refer to a process in which companies leverage each other's strengths and resources to achieve mutual benefits and success. For instance, in June 2023, Spark New Zealand, a New Zealand-based telecommunications company, partnered with Lynk Global., a US-based developer of satellite-to-mobile-phone satellite constellations. With this partnership, they aim to launch a satellite-to-mobile service, aiming to enhance connectivity for its customers, address key challenges, capitalize on emerging opportunities, and position themselves as a leader in innovative connectivity solutions for the New Zealand market.

Which Major Organizations Influence the Direction of the Mobile Satellite Services Market?

Major companies operating in the mobile satellite services market are Ericsson AB, Telstra Corporation Limited, Singapore Telecommunications Limited., Viasat Inc., Intelsat SA, SES S.A., EchoStar Corporation, Hughes Network Systems, AI Yah Satellite Communications company P.J.S.C, Inmarsat plc, Eutelsat Communications S.A., Telesat Canada, Iridium Communications Inc., Telespazio S.p.A., Comtech Telecommunications Corporation, Orbcomm Inc., Encompass Digital Media Inc., Speedcast International Limited, Globecast Asia Pte Ltd, Gilat Satellite Networks Ltd., Globalstar Inc., Avanti Communications Group plc, Ligado Networks LLC, Russian Satellite Communications Company (RSCC), MTN Satellite Communications Inc.

Get the detailed mobile satellite services market report today

https://www.thebusinessresearchcompany.com/report/mobile-satellite-services-global-market-report (https://www.thebusinessresearchcompany.com/report/mobile-satellite-services-global-market-report)

Which Region Holds the Largest Share of the Mobile Satellite Services Market?

North America was the largest region in the Mobile Satellite Service market in 2024. North America is expected to be the fastest-growing region in the forecast period. The regions covered in the mobile satellite services market report are Asia-Pacific, Western Europe, Eastern Europe, North America, South America, Middle East, Africa.

#Contact Us:#

The Business Research Company: Market Research Reports (https://thebusinessresearchcompany.com/)

Americas +1 310-496-7795

Asia +44 7882 955267 & +91 8897263534

Europe +44 7882 955267

Email: info@tbrc.info (mailto:info@tbrc.info)

#Follow Us On:#

LinkedIn: The Business Research Company | LinkedIn (https://in.linkedin.com/company/the-business-research-company)

Global Mobile Satellite Services Market Projected to Strengthen in Value and Scale by 2029

Grab 20% Off With Code ONLINE20 On Global market Reports – Evaluate Global Trends, Market Risks, and Competitive Intelligence

What Is the Predicted Market Size and CAGR of the Mobile Satellite Services Market by the End of the 2029?

The mobile satellite services market size has grown strongly in recent years. It will grow from $5.34 billion in 2024 to $5.68 billion in 2025 at a compound annual growth rate (CAGR) of 6.4%. The growth in the historic period can be attributed to emergence of global connectivity needs, increased military and defense applications, expansion of broadcasting and media, enterprise connectivity, telecommunications backhaul.

The mobile satellite services market size is expected to see strong growth in the next few years. It will grow to $7.07 billion in 2029 at a compound annual growth rate (CAGR) of 5.6%. The growth in the forecast period can be attributed to emerging market growth, commercial space activities, smart transportation, increased agriculture and precision farming, adoption of smart transportation. Major trends in the forecast period include integration with 5G networks, rapid expansion of IoT connectivity, increasing demand for broadband connectivity, enhanced disaster response and public safety solutions, diversification of service offerings.

Get your free report sample today:

Mobile Satellite Services Market Size and Growth Report 2025 Sample (https://www.thebusinessresearchcompany.com/sample.aspx?id=14143&type=smp)

What Are the Significant Market Forces Driving the Mobile Satellite Services Market Performance?

The expansion of oil and gas exploration is expected to propel the growth of the mobile satellite services market going forward. Oil and gas exploration refers to the process of searching for underground or underwater reservoirs of oil and natural gas deposits. It is rising due to economic, technological, and geopolitical factors to meet global energy needs. Mobile satellite services are used in oil and gas exploration activities to offer dependable communication, data transmission, logistics assistance, and environmental monitoring in remote and challenging environments. For instance, in March 2024, according to the Energy Information Administration, a U.S-based government agency U.S. crude oil production grew by 9% in 2023 compared to 2022, reaching a record 12.9 million barrels per day. This increase has driven higher crude oil exports, despite U.S. refineries continuing to be optimized for processing heavier crude oils. Therefore, the expansion of oil and gas exploration is driving the growth of the mobile satellite services market.

Which Segments Are Likely to Shape the Future Outlook of the Mobile Satellite Services Market?

The mobile satellite servicesmarket covered in this report is segmented –

1) By Service: Voice, Data

2) By Application: Land Mobile Satellite Service, Aeronautical Mobile Satellite Service, Maritime Mobile Satellite Service

3) By Industry: Oil And gas, Media And Entertainment, Transportation, Aviation, Defense, Automative, Government, Other Industries

Subsegments:

1) By Voice: Satellite Phone Services, Push-To-Talk Services

2) By Data: Internet Access Services, Remote Monitoring And Control Services

Which Future-Ready Trends Are Expected to Influence the Mobile Satellite Services Market?

Major companies operating in the mobile satellite service industry are adopting a strategic partnership approach to provide resilient and reliable connectivity, particularly in remote and rural areas where terrestrial infrastructure is insufficient. Strategic partnerships refer to a process in which companies leverage each other's strengths and resources to achieve mutual benefits and success. For instance, in June 2023, Spark New Zealand, a New Zealand-based telecommunications company, partnered with Lynk Global., a US-based developer of satellite-to-mobile-phone satellite constellations. With this partnership, they aim to launch a satellite-to-mobile service, aiming to enhance connectivity for its customers, address key challenges, capitalize on emerging opportunities, and position themselves as a leader in innovative connectivity solutions for the New Zealand market.

Which Major Organizations Influence the Direction of the Mobile Satellite Services Market?

Major companies operating in the mobile satellite services market are Ericsson AB, Telstra Corporation Limited, Singapore Telecommunications Limited., Viasat Inc., Intelsat SA, SES S.A., EchoStar Corporation, Hughes Network Systems, AI Yah Satellite Communications company P.J.S.C, Inmarsat plc, Eutelsat Communications S.A., Telesat Canada, Iridium Communications Inc., Telespazio S.p.A., Comtech Telecommunications Corporation, Orbcomm Inc., Encompass Digital Media Inc., Speedcast International Limited, Globecast Asia Pte Ltd, Gilat Satellite Networks Ltd., Globalstar Inc., Avanti Communications Group plc, Ligado Networks LLC, Russian Satellite Communications Company (RSCC), MTN Satellite Communications Inc.

Get the detailed mobile satellite services market report today

https://www.thebusinessresearchcompany.com/report/mobile-satellite-services-global-market-report (https://www.thebusinessresearchcompany.com/report/mobile-satellite-services-global-market-report)

Which Region Holds the Largest Share of the Mobile Satellite Services Market?

North America was the largest region in the Mobile Satellite Service market in 2024. North America is expected to be the fastest-growing region in the forecast period. The regions covered in the mobile satellite services market report are Asia-Pacific, Western Europe, Eastern Europe, North America, South America, Middle East, Africa.

#Contact Us:#

The Business Research Company: Market Research Reports (https://thebusinessresearchcompany.com/)

Americas +1 310-496-7795

Asia +44 7882 955267 & +91 8897263534

Europe +44 7882 955267

Email: info@tbrc.info (mailto:info@tbrc.info)

#Follow Us On:#

LinkedIn: The Business Research Company | LinkedIn (https://in.linkedin.com/company/the-business-research-company)

0 Comentários

0 Compartilhamentos

5K Visualizações