As a result of this the consumption of zinc is necessary

The most pure form of zinc possesses and exhibits a number of qualities and characteristics, some of which are listed below. These qualities and characteristics include:

The complete version of ZAMEK 3 in all of its dazzling glory. In addition to the other qualities that were discussed earlier in this paragraph, the process of casting can be performed with this material with relative ease because its melting point is only 384 degrees Celsius. This is in addition to the other qualities that were discussed. As a direct consequence of this fact, casting is generally considered to be the most common application of this technique within the manufacturing sector of the economy.

When copper is added to a zinc alloy, the combined material possesses increased tensile and compressive strength as a result of the transformation.

1. The number 8 is one of the components that make up the aluminum-zinc alloy that is known as ZA 8

2. Other components that make up the alloy include zinc and aluminum

3. Additionally, it is compatible with a variety of surface finishing processes, which makes it a popular choice for the production of items that are meant to be used for decorative purposes due to the versatility it offers in this regard

4. Due to the versatility it offers, it is a popular choice for the production of items that are meant to be used for decorative purposes

5. Because of the flexibility it provides, it is a material of choice that is frequently utilized in the manufacturing of items that are designed to be used for decorative purposes

6. Because of the adaptability it offers, it is frequently used as the material of choice in the manufacturing of items that are intended to be used in a decorative capacity

7. This is because of the fact that it can be used in a variety of settings

8. For the sake of brevity, we will henceforth simply refer to it as EZAC

One of the primary reasons why it is commonly considered to be the best grade of zinc alloy that is commonly used is due to the fact that it possesses exceptional levels of strength, hardness, and creep performance. In other words, it has these characteristics in exceptional amounts. The fact that it is generally considered to be the highest quality of zinc alloy that is utilized is also one of the primary reasons why it is used.5% copper, making it yet another zinc alloy that also has a high content of aluminum and contains a high percentage of that metal. In other words, it contains a high percentage of that metal. In addition, in comparison to a wide variety of other zinc alloys, it has a melting point that is relatively high. This, combined with the fact that it is suitable for the process of cold chamber die casting due to its suitability for the procedure, makes it an excellent material to use.

Because it has a golden sheen, it is frequently used in the production of items that have an ornamental value such as medals, decorative pieces, and buttons. This is due to the fact that it can be polished to a very fine finish. This is as a result of the fact that it is capable of having a very fine finish after being polished. This is because it has the appearance of gold, which accounts for why it is valued so highly. The aerospace industry is one of the most important and widespread applications for this material. It also has one of the most important and widespread applications. However, just like any other material, they exhibit certain behaviors that necessitate machinists taking into account certain factors and making appropriate adjustments in order to achieve the results that they desire. These behaviors require machinists to take into account certain factors and make appropriate adjustments. Machinists are required to take into account certain behaviors that the materials are known to exhibit in order to achieve the desired results. As a result of these behaviors, machinists are required to take into consideration a number of factors and make adjustments as required.

having a point of melting that is lower than the typical value for its type; distinguishable by this property.

In a similar fashion, thermal softening can sometimes prevent machinists from approaching the machining process in an aggressive manner. This can be frustrating for both parties. Participating in activities of this nature requires that adequate ventilation be available at all times. This requirement must always be met. This is something that should not be done.

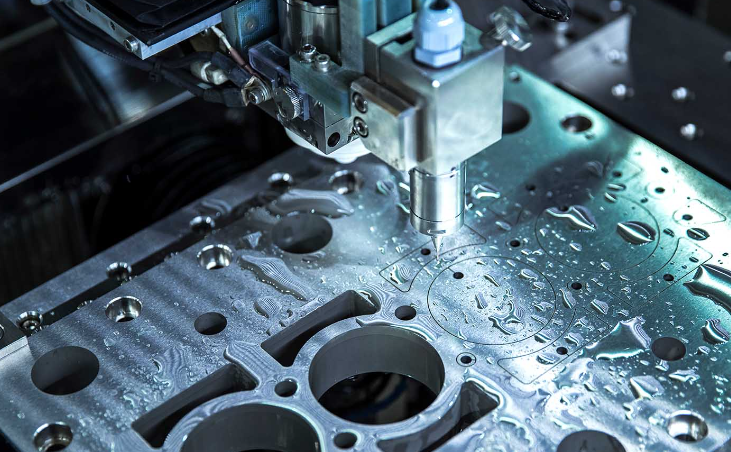

The machining of zinc alloy can result in a wide variety of distinct looks and can be carried out using a variety of different techniques. When it comes to the production of angular and prismatic shapes, this method is the one that should be used instead of any other method and should take precedence over all others. The most sophisticated lathes are able to perform turn-milling operations in addition to being able to perform multiple axes of motion with a high degree of precision. These lathes are also able to perform other advanced motions. Additionally, these lathes are able to perform turn-milling operations simultaneously. Before beginning the process of drilling zinc alloys, it is highly recommended to make use of flood cooling and drill bits that have been sharpened in advance. This is due to the fact that drilling zinc alloys can generate heat, which can cause the material to become ruined. The application of this measure will have the effect of reducing the amount of heat that is produced in the cutting zone, which is the intended consequence of the measure. The die casting process cannot move forward until this necessary prerequisite step has been finished first.

Electroplating: Zinc alloys have the capability of supporting electroplating with materials such as nickel and cobalt, which enables the achievement of specific surface finishes, properties, and enhanced corrosion resistance. Zinc alloys can also support electroplating with materials such as nickel and cobalt. Electroplating with materials such as nickel and cobalt is something that can be done on zinc alloys as well.

In addition to this, before making a decision, you need to make sure that the coolant you choose is one that is predominantly made up of water so that you can avoid any unpleasant surprises in the future. This is necessary in order to protect yourself from any potential complications.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- الألعاب

- Gardening

- Health

- الرئيسية

- Literature

- Music

- Networking

- أخرى

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness