How do I determine which type of material will work best for my CNC machining project

When it comes to choosing a material for CNC machining, there are a few key considerations that absolutely have to be given attention to first. This is essential in order to manufacture the components that will fulfill the requirements of the production process in order for it to be successful.

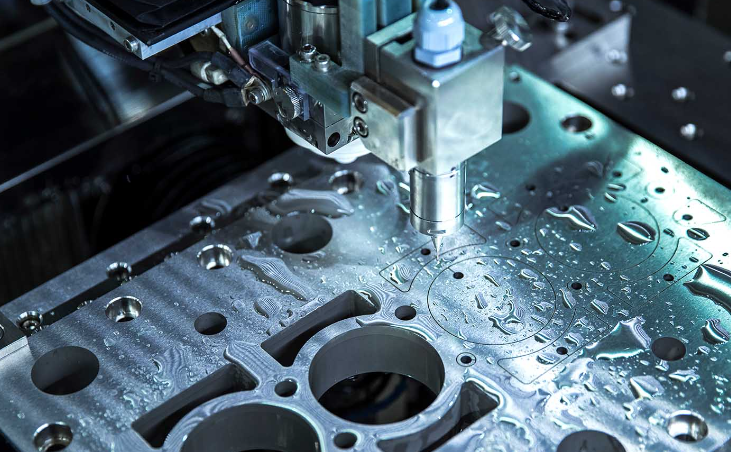

Working with a wide range of different kinds of materials is a necessary part of the CNC machining process.

-

Machining, also known as CNC machining, is a versatile process that enables the utilization of a wide variety of materials

-

CNC machining is accomplished through the utilization of computer numerical control, also known as CNC

-

It is possible to machine not only the typical plastics and metals using a computer numerically controlled machine (CNC), but also other materials such as wood, ceramics, and composites

-

Other than that, it is possible to machine plastics and metals

In this article, we will concentrate more on plastic and metal as machining materials because these materials have a wider variety of applications across a number of different industries. The reason for this is that plastic and metal are the most common materials used in machining. These CNC materials provide a number of benefits, including resistance to thermal stress, high levels of strength and hardness, and excellent electrical conductivity. These are just a few of the benefits. The following types of metals are frequently utilized in CNC machines:

The first element is aluminum. In addition to this, it can be machined, albeit to a lesser extent than aluminum. In addition to this, it possesses a remarkable strength-to-weight ratio, is astonishingly lightweight, is resistant to corrosion, and possesses an alluring silvery appearance.

Its resistance to wear and corrosion, along with its exceptional strength and tenacity, make stainless steel a material of exceptional quality. Stainless steel is also tenacious and strong. Additionally, CNC machines frequently make use of stainless steel grades 303, 304, and 316. These grades are known as 303, 304, and 316, respectively.

steel materials that were fabricated into various component forms

3. Carbon steel by itself, in addition to a number of different carbon steel alloys

Carbon steel and the alloys that are closely related to it are excellent materials for a wide variety of applications. Carbon steel is known for its exceptional strength, and the alloys that are closely related to it are also machinable. They are compatible with a wide variety of heat treatment processes, all of which are effective at enhancing the material's mechanical properties, and they are compatible with these processes. In addition, these processes are effective at enhancing the material's mechanical properties.

Due to copper's high conductivity, it is well known for having excellent conductivity in both thermal and electrical currents. Copper's excellent conductivity has earned it a reputation. Additionally, due to its high conductivity, it is an excellent material for use in electrical and electronic applications. Copper is utilized in a wide range of industries, some of which include the production of jewelry, magnetic devices, and electrical wire, amongst other things. Copper is also utilized in a number of other applications. Copper and zinc are the two primary elements that go into the production of brass. It can frequently be discovered in consumer goods, low-strength fasteners, plumbing equipment, and electrical apparatus. Bronze has a high degree of machinability, which enables it to be used in the manufacturing of precision components such as gears, bearings, and other gears and bearings. This makes it possible to use bronze in the production of other gears and bearings as well.

Titanium, despite its relatively low weight in comparison to other metals, possesses remarkable strength. To put it another way, it has a very high level of durability while at the same time maintaining a weight that is not at all excessive. The biomedical industry is an example of one of these.

Titanium is also utilized in the manufacturing of high-performance machined parts for a wide range of industries, including the military, the aerospace industry, and the medical field, among others. Titanium is also utilized in the production of aerospace vehicles like airplanes and spaceships. Titanium is a material that is utilized quite frequently in CNC machine tools in today's modern world. cnc milling online is the material of choice for high-temperature components, such as those found in engines, because it possesses excellent thermal characteristics, which makes it the ideal choice for these components and makes it the material of choice for high-temperature components.

Machining magnesium is notorious for its tendency to ignite, and it can be more expensive than processing other types of metals. In comparison to a number of other metals, including aluminum, magnesium has a lower resistance to corrosion. This is another disadvantage of magnesium.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Spellen

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Other

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness