Polishing is a method of surface treatment that is frequently used with the intention of polishing consumer goods

The term "surface finishing" refers to a number of distinct industrial processes that are used to modify the surface of a manufactured item, product, or component in order to achieve or improve a property or characteristic. These processes are collectively known by the term "surface finishing."The finishing of a surface can be utilized to accomplish or improve a wide variety of properties and characteristics. The terms "surface finishing" and "surface treatment" are interchangeable and can be used in either setting. Similarly, the terms "surface finishing" and "surface treatment"The Surface Finish Services of a component plays a significant role in determining how the component will appear, how it will feel, and how it will perform. It is essential to have a good surface finish in order to design a successful product, and it is also essential to have a good surface finish in order to design a product that is successful. It is essential for us to have an understanding of the many different processes that can be used to treat the surface of an object in addition to gaining knowledge of software and product design. Because of this, we will have the chance to acquire a more in-depth understanding of product design. The following are a few examples of surface finishing processes that are utilized for consumer goods on a fairly consistent basis.

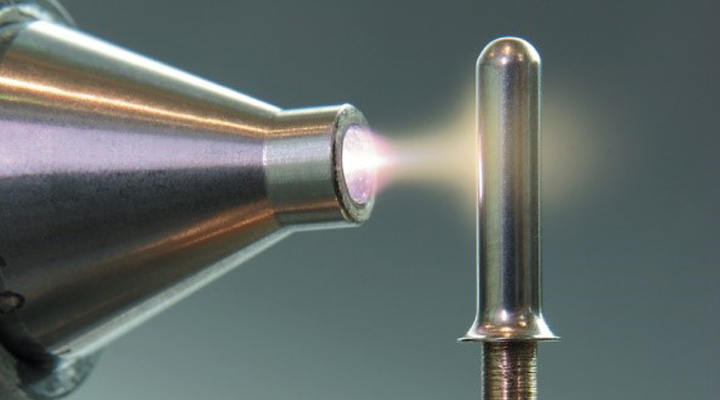

#1 The oxidation that is triggered when plasma is subjected to an electrolysis process

The Plasma Electrolytic Oxidation (PEO) process is an electrochemical method that generates a plasma discharge at the metal-electrolyte interface by applying a high voltage. The plasma discharge is used to oxidize the metal. The surface of the substrate is turned into a layer of dense and brittle ceramic oxide by employing this method, and this transformation takes place without the substrate sustaining any damage as a result of the substrate being subjected to thermal expansion. Plasma discharges take place whenever the applied voltage is greater than the breakdown value, which is typically somewhere in the range of a few hundred to a few thousand volts. Plasma discharges can also take place when the voltage is lower than the breakdown value. When the breakdown value is exceeded, there is also a possibility of plasma discharges happening. The subfield of surface engineering known as plasma electrolytic oxidation is experiencing a period of rapid expansion at the moment. This can be seen most clearly in the manner in which magnesium-titanium-aluminum alloys are processed using this method. Magnesium, titanium, and aluminum are the constituent elements of these alloys.

#2 Polished to a mirrorlike sheen using a brush

It is common practice to also refer to brushed polish or dull polish as a satin finish or dull finish. This is because brushed polish and dull polish have very similar appearances. This is due to the fact that brushed polish and dull polish have extremely comparable visual qualities. In order to manufacture it, there are two steps that must be taken first: polishing the metal with a belt or wheel that has a grit range of 120–180, and then softening it with either a greaseless compound that has a grit range of 80–120, or a medium non-woven abrasive belt or pad. Both of these options are necessary in order to produce it.

Metals like stainless steel, aluminum, and nickel are some examples of the types of metals that are brushed on a regular basis. Other types of metals include brass and bronze. The use of brushed finishes is becoming increasingly popular across a diverse array of product categories, including whiteware, small appliances, architectural design, and automotive design, to name a few of these areas of application. Stainless steel with a brushed finish was used to construct the Gateway Arch as well as the exterior of the DeLorean time machine owned by the DeLorean time machine club. Surface roughness, also known as the degree to which the finish has been brushed, is typically measured in the range of 0.5–1.5 micrometers Ra. This range can also be thought of as the amount of brushing done. The amount of brushing that was done can also be thought of as falling within this range.

#3 Vitreous enamel

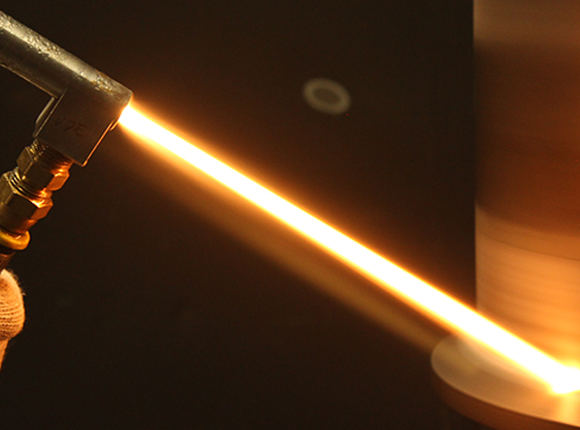

Vitreous enamel is a type of enamel that is created by fusing powdered glass to a substrate at temperatures ranging from 1,380 to 1,560 degrees Fahrenheit (750 to 850 degrees Celsius). It is also known as porcelain enamel. The end result of this process is the formation of a surface that is extremely tough and long-lasting. The powder will first transform into a liquid, after which it will flow, and finally it will solidify into a vitreous coating that is both smooth and long-lasting. Enamels, on the other hand, are most commonly used on metals, but they can also be used on surfaces made of glass and ceramics if the right conditions are met. The use of enamels on metals is by far the most common application. Enamels have the capacity to color a variety of metals, including copper, silver, and gold, which they are applied to. Enamels can also be used in a variety of other applications. It is possible to apply glass powder to a surface in either a wet or dry state, depending on which method is chosen. If you apply heat to the enamel, it will begin to melt, flow, and eventually fuse to the surface.

This will result in the formation of a smooth coating on the surface of the object, as the enamel will have fused to the surface. Whether a torch or a kiln is used to conduct the firing, the temperature of the process will typically range between 1400 and 1650 degrees Fahrenheit. This is true despite the fact that the method of firing may vary. Because the manner in which enamels are fired has an effect on the texture and color of the enamel design, enamelists are required to take into consideration a variety of factors before they fire their piece. This is because the manner in which enamels are fired has an impact. Enamelists are required to fire their pieces in a particular order because of the impact that this has.

Beads were used as projectiles in the fourth explosion.

Bead blasting is a process that can be used to give a finished appearance to a wide variety of different products. This effect can be achieved by using glass beads. The step-by-step procedure of bead blasting can be broken down even further into its component, which is referred to as shot blasting. For the purpose of either cleaning or polishing a surface, one method that may be utilized in this process to accomplish either of those goals is the high-pressure ejection of small glass beads. Bead blasting is a technique that can be used to produce a surface that is not only smooth, but also shiny, and completely free of any blemishes or other imperfections. Bead blasting is a process that is used in manufacturing to achieve a surface finish that is desirable on a variety of materials, including metals, plastics, glasses, and rubber. Bead blasting is a process that is used in manufacturing to achieve Surface Finish Services that is desirable on a variety of materials. Bead blasting is one technique that can be utilized to give a material this type of surface finish.

#5 Sandblasting

Sandblasting, which is also known as abrasive blasting, is a method of surface finishing that involves spraying abrasive particles against a surface at a high rate of pressure using a powered machine, which typically also includes an air compressor in addition to a sandblasting machine. Sandblasting is also sometimes referred to as abrasive blasting. Abrasive blasting is another name that is sometimes used to refer to sandblasting. This technique is known as "sandblasting," and it gets its name from the fact that it involves hurling sand particles at the surface in order to remove material from the surface. Sand particles, when they collide with the surface, produce a texture that is more even and smoother. This is because sand particles are made up of very small particles. This is due to the fact that sand particles are composed of incredibly minute particles.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Игры

- Gardening

- Health

- Главная

- Literature

- Music

- Networking

- Другое

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness