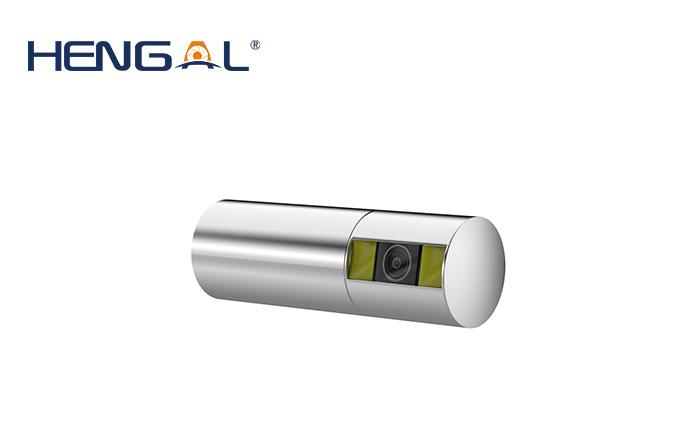

Endoscopic Camera Module overall requirements

First of all, we must understand the internal structural characteristics of the workpiece, detect the specific content, and location, and expand the relevant link instruments in accordance with the program to check whether the power supply is reliable, and the position of the instrument is stable.

The second is to select Endoscopic Camera Module suitable probes, lenses and channels to enter the product. Before detection, you should clearly clear the obstacles in the channel, burrs, etc.

Third, for some products that cannot be understood or complicated internally, you can use observation lens to observe and test. Try to make the lens in the detection area as much as possible during the detection.

Fourth, before testing, the eyes should be adapted to the detection environment and shallow, and when working for a long time, pay attention to avoid eye fatigue, which causes the missed inspection.

Fifth, be careful during the testing process to ensure that the probe arrives smoothly when the specified site and the probe encounters obvious resistance during the promotion process. It should be stopped immediately. When the probe exits, it should be slow. Probe.

Sixth, the collected image is processed and analyzed.

Seventh, clean the probe in accordance with regulations, organize instruments and lives.

Eighth is that the recommended staff can use the auxiliary workers to help the probe to reach the*good position.

Nine is to use Endoscopic Camera Module devices including industrial endoscopes and probes types, diameter, and models, and the location and accuracy of industrial endoscope measurement.

Ten is the requirements of the test report.

endoscopic camera module https://www.hengal-tech.com/4-5mm-medical-endoscope-camera-module-4-5mm-pshow/17.html

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Giochi

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Altre informazioni

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness