Thermal Energy Storage

Thermal Energy Storage Solutions in the Middle East & Africa: Optimising Cooling Efficiency with API Energy

Thermal Energy Storage for District Cooling and Power Plants in MEA

The Middle East and Africa (MEA) region faces some of the highest cooling demands globally, driven by extreme ambient temperatures, rapid urbanisation, large-scale infrastructure projects, and expanding district energy networks.

In this environment, Thermal Energy Storage(TES) has become a strategic solution for improving energy efficiency, reducing operational costs, and ensuring reliable cooling performance.

API Energy Thermal Energy Storage Tanks are specifically designed to support cooling plants with variable day-night demand, a common operational scenario for district cooling plants, power plants, and turbine inlet air cooling (TIAC) systems across MEA.

Why Thermal Energy Storage Is Critical for the Middle East & Africa

Addressing Peak Cooling Demand

In MEA, cooling demand typically peaks during the daytime and drops significantly at night. Operating chillers continuously at peak capacity leads to:

- Higher capital expenditure (CAPEX)

- Increased energy consumption

- Reduced equipment lifespan

Thermal Energy Storage systems allow energy to be generated during off-peak hours and used when demand is highest, creating a more balanced and cost-effective operation.

Supporting District Energy Plants

District cooling plants often serve commercial districts, airports, data centres, hospitals, and industrial zones. TES tanks:

- Smooth demand fluctuations

- Improve plant load management

- Reduce reliance on oversized chillers

How API Energy Thermal Energy Storage Tanks Reduce Costs

Lower Capital and Operational Costs

API Energy TES tanks:

- Reduce the required installed chiller capacity

- Minimise peak electricity demand charges

- Lower operational and maintenance expenses

This is especially beneficial for district energy plants and turbine inlet air cooling systems designed for peak load conditions.

Optimised Turbine Inlet Air Cooling (TIAC)

When TIAC systems are designed for peak demand, integrating a TES tank allows:

- Storage of cooling energy during low-load periods

- Instant cooling availability during high-temperature conditions

- Improved turbine efficiency and power augmentation

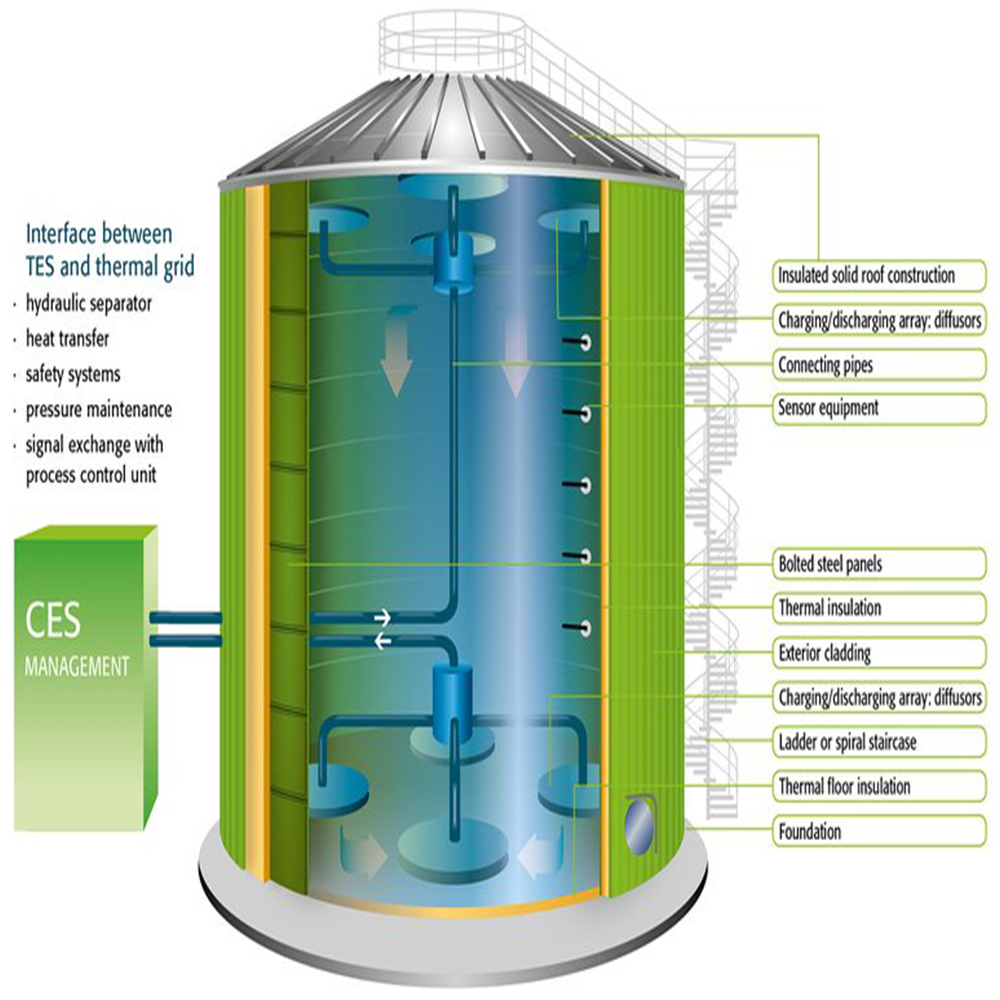

Advanced TES Tank Design by API Energy

API Energy designs, manufactures, and installs state-of-the-art thermal energy storage solutions that are fully customised to meet regional climate and operational needs.

Flexible Tank Materials for Every Application

API Energy selects the most suitable and efficient materials based on the storage medium and operating environment:

- Glass-Fused-to-Steel (GFS) tanks – ideal for long service life and corrosion resistance

- Powder-Coated Steel tanks – cost-effective and durable

- Stainless Steel tanks – for demanding industrial applications

- Galvanised Steel tanks – suitable for specific climatic and budget requirements

This flexibility makes API Energy TES tanks ideal for dessert, coastal, and industrial environments across MEA.

Expandable, Relocatable, and Custom-Built Storage Tanks

Modular and Future-Ready Design

API Energy TES tanks:

- Can be easily extended to increase storage capacity

- Can be disassembled or relocated as project needs evolve

- Support both temporary and permanent installations

Open or Covered Tank Solutions

Storage tanks can be supplied as:

- Open tanks

- Tanks with various roof and cover solutions, depending on:

- Climate conditions

- Evaporation control

- Safety and environmental requirements

Ice Thermal Energy Storage: High-Efficiency Cooling Technology

How the API Energy Ice Generator Works

API Energy’s Ice Thermal Energy Storage system accumulates energy by generating ice, providing high energy density and exceptional cooling performance.

Key Components

- Evaporator located in the upper section

- Storage tank in the lower section

- Two pumps:

- One for the charging period

- One for the discharging period

Charging Period (Ice Generation)

During charging:

- Water freezes inside the cooling coils

- Part of the water drops into the tank in liquid form

- The remaining ice stays within the coils, acting as a condenser

Discharging Period (Cooling Delivery)

During discharging:

- Chilled water is pumped from the bottom of the tank

- It circulates through the cooling coils of the load

- After absorbing heat, water returns to the ice generator

- At higher temperatures, ice formation stops, and cold water is delivered instead

This process ensures continuous cooling availability, even during peak demand.

Key Applications of API Energy TES Systems in MEA

- District cooling plants

- Power plants and combined cycle plants

- Turbine inlet air cooling systems

- Airports and large commercial complexes

- Industrial facilities and data centres

- Healthcare and mission-critical infrastructure

Why Choose API Energy for Thermal Energy Storage?

- Proven expertise in power augmentation and energy efficiency

- Fully tailor-made TES solutions

- High-quality European engineering standards

- Materials optimised for harsh MEA climates

- Long-term reliability and scalability

API Energy delivers measurable performance improvements while supporting sustainability and energy optimisation goals.

Frequently Asked Questions (FAQs)

What is Thermal Energy Storage and how does it work?

Thermal Energy Storage (TES) stores cooling energy during off-peak hours and releases it during peak demand, reducing energy costs and improving system efficiency.

Why is TES ideal for the Middle East and Africa?

The MEA region experiences extreme heat and variable daily cooling demand. TES helps manage peak loads, reduce electricity consumption, and improve plant reliability.

Can API Energy TES tanks be expanded in the future?

Yes. API Energy tanks are modular and can be extended, relocated, or reconfigured as project requirements change.

What materials are used in API Energy TES tanks?

API Energy offers glass-fused-to-steel, powder-coated steel, stainless steel, and galvanised steel tanks depending on the application and environment.

What is Ice Thermal Energy Storage used for?

Ice TES is used where high energy density is required, allowing compact systems with powerful cooling output for district energy and industrial applications.

How does TES reduce capital and operational costs?

TES reduces the need for oversized chillers, lowers peak electricity demand, and improves equipment lifespan, resulting in lower CAPEX and OPEX.

Connect with API Energy

For expert advice on Thermal Energy Storage solutions in the Middle East & Africa, contact API Energy today.

Email: info@apienergy.co.uk

Visit:https://apienergy.co.uk/product/api-energy-thermal-energy-storage-tes-water-ice

Follow Us on Social Media

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Jeux

- Gardening

- Health

- Domicile

- Literature

- Music

- Networking

- Autre

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness