Milking Robots Market Size, Share & Growth Analysis 2026-2034

Market Overview:

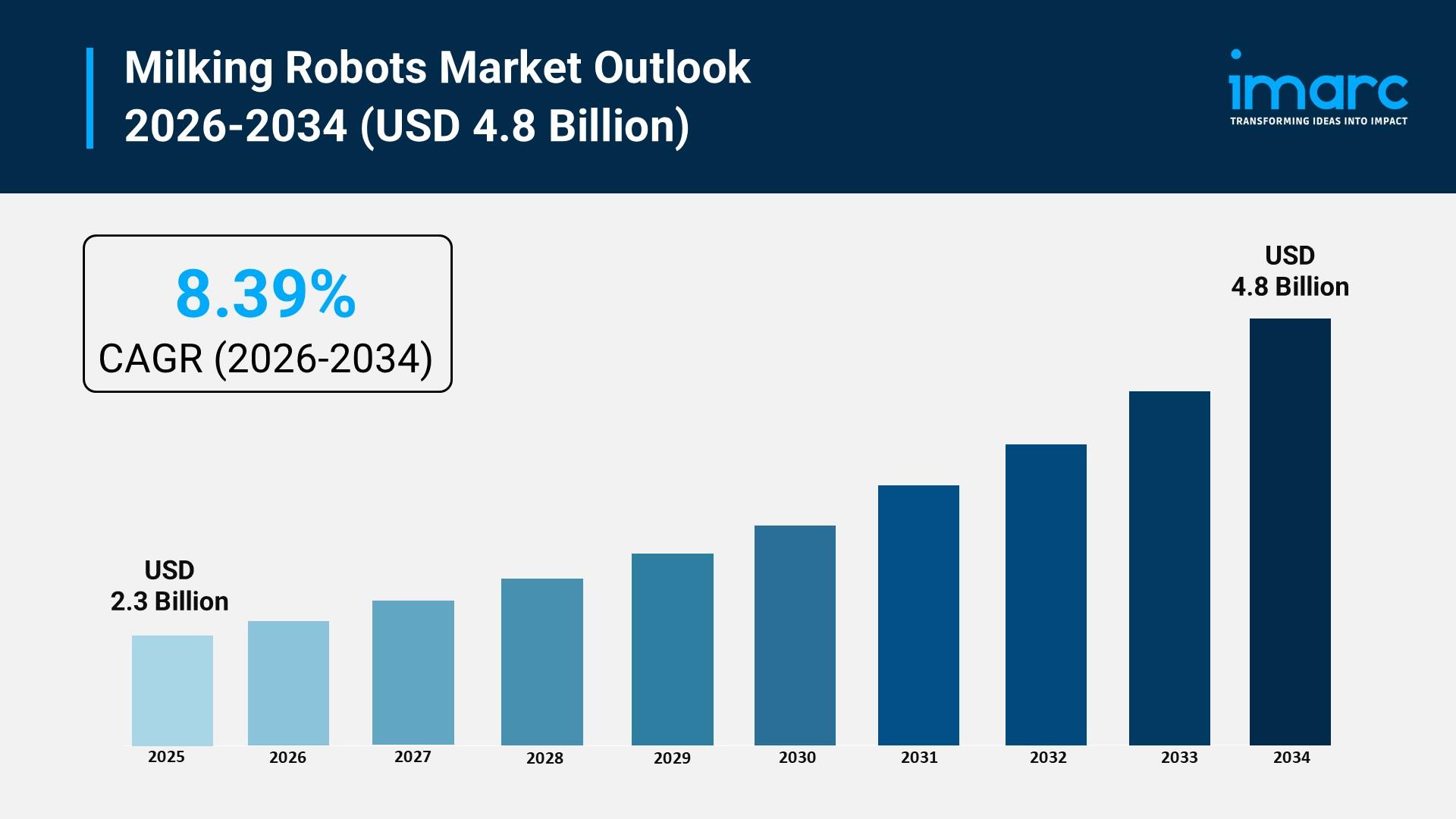

The milking robots market is experiencing rapid growth, driven by labor shortages and rising operational costs, increasing global demand and productivity needs, and technological integration and precision dairy farming. According to IMARC Group’s latest research publication, “Milking Robots Market Report by Offering (Hardware, Software, Services), Type (Single-Stall Unit, Multi-Stall Unit, Rotary System), Herd Size (Up to 100, Between 100-1,000, Above 1,000), and Region 2026-2034”, The global milking robots market size reached USD 2.3 Billion in 2025. Looking forward, IMARC Group expects the market to reach USD 4.8 Billion by 2034, exhibiting a growth rate (CAGR) of 8.39% during 2026-2034.

This detailed analysis primarily encompasses industry size, business trends, market share, key growth factors, and regional forecasts. The report offers a comprehensive overview and integrates research findings, market assessments, and data from different sources. It also includes pivotal market dynamics like drivers and challenges, while also highlighting growth opportunities, financial insights, technological improvements, emerging trends, and innovations. Besides this, the report provides regional market evaluation, along with a competitive landscape analysis.

Download a sample PDF of this report: https://www.imarcgroup.com/milking-robots-market/requestsample

Our report includes:

- Market Dynamics

- Market Trends and Market Outlook

- Competitive Analysis

- Industry Segmentation

- Strategic Recommendations

Growth Factors in the Milking Robots Market

- Labor Shortages and Rising Operational Costs

The persistent global challenge of attracting and retaining agricultural labor is a primary driver for the adoption of automated milking systems. In major dairy farming regions, wage inflation for farmhands is substantial; for example, US Department of Agriculture data indicates a significant increase in farm wages over a recent five-year period. This escalating operational expense, coupled with the difficulty of securing reliable manual labor for the repetitive task of milking, is accelerating the shift toward robotics. Automated milking systems (AMS) offer a proven solution by enabling farms with larger herd sizes (typically 100 to 1,000 cows) to maintain or increase productivity while reducing dependency on a shrinking workforce. The deployment of a multi-stall unit, which can service a large number of cows with minimal human intervention, becomes an economic necessity to sustain profitable commercial dairy operations.

- Increasing Global Demand and Productivity Needs

The growing worldwide demand for milk and dairy products, driven by population growth and rising disposable incomes in emerging economies, puts immense pressure on dairy farms to maximize efficiency and output. Robotic systems directly address this by allowing for increased milking frequency compared to traditional scheduled milking, which can lead to a quantifiable rise in milk production per cow (reported in some studies to be in the range of 5%–10% higher). Furthermore, the trend toward farm consolidation into larger, centralized operations, particularly in developed markets, makes high-throughput systems like automated milking rotaries economically essential. These rotaries are designed for large-scale enterprises and can service hundreds of cows daily, providing the scale and productivity required to meet the accelerating global consumption of dairy.

- Technological Integration and Precision Dairy Farming

The continuous integration of advanced technologies like the Internet of Things (IoT), sensors, and Artificial Intelligence (AI) into milking robots is making them sophisticated farm management tools. Modern AMS go beyond simple milk extraction; they feature real-time monitoring capabilities, utilizing sensors and analyzers to collect data on each cow’s milk yield, milk quality (such as fat, protein, and somatic cell count), and overall health indicators. This granular data enables precision dairy farming, allowing farmers to detect potential health issues like mastitis early. DeLaval, for instance, has developed technology that analyzes milk flow throughout the entire process to optimize the vacuum applied, which can minimize milking time by up to one-tenth and further enhance cow comfort and yield. This technological advancement is improving farm efficiency and animal welfare, driving further investment.

Key Trends in the Milking Robots Market

- AI and Machine Learning for Predictive Health

A significant emerging trend is the deeper integration of Artificial Intelligence (AI) and Machine Learning (ML) to transform milking robots from simple automation tools into predictive health and management systems. Current systems already monitor activity and milk composition, but the newest applications use AI algorithms to analyze vast streams of data to anticipate issues before symptoms manifest. For example, by tracking subtle changes in a cow’s movement patterns, feeding behavior, and milk conductivity over time, the system can predict the onset of a disease like ketosis or mastitis up to several days earlier than manual inspection. Companies are now offering cloud-based data analytics subscriptions that provide farmers with actionable, predictive insights, allowing for targeted intervention and a reduction in herd treatment, thereby improving overall animal health and productivity.

- Shift to Automated Milking Rotaries for Large Herds

While single and multi-stall units have been the foundational systems, there is a clear trend toward the adoption of Automated Milking Rotaries (AMRs) for very large-scale dairy farms. This system, which consists of a continuously revolving platform where cows are automatically attached and milked, offers a high-throughput solution that maximizes efficiency for herds exceeding a significant threshold of animals. These units are being designed to handle a massive number of milking opportunities daily, making them essential for commercial farms that manage many hundreds of cows. Leading manufacturers are investing in this segment, with new rotary models focusing on robust design and rapid throughput to cater to the increasing number of large, industrial-scale dairy operations globally that require highly centralized and efficient milking.

- Ecosystem Services and Remote Monitoring

The milking robot market is increasingly focusing on the Service segment as an emerging revenue stream, moving beyond the sale of hardware. This trend involves comprehensive service packages, including system integration, customized training, and connectivity services. Farmers are demanding seamless, uninterrupted operation, driving the need for sophisticated predictive maintenance and remote monitoring capabilities. For instance, manufacturers are deploying robust support networks where technicians can remotely diagnose and troubleshoot systems via cloud connectivity, often reducing downtime for maintenance by a measurable margin. This shift ensures long-term robot functionality and allows farmers to access critical data and operational support from any location, effectively transforming the dairy farm into a connected, data-driven enterprise.

Leading Companies Operating in the Milking Robots Industry:

- Afimilk Ltd.

- BouMatic Robotics

- Dairymaster

- DeLaval (Tetra Laval)

- Fullwood Ltd.

- GEA Group AG

- Lely Industries N.V.

- Read Industrial Ltd.

- System Happel

- Waikato Milking Systems NZ LP.

Milking Robots Market Report Segmentation:

By Offering:

- Hardware

- Software

- Services

By Type:

- Single-Stall Unit

- Multi-Stall Unit

- Rotary System

By Herd Size:

- Up to 100

- Between 100-1,000

- Above 1,000

Regional Insights:

- North America (United States, Canada)

- Asia Pacific (China, Japan, India, South Korea, Australia, Indonesia, Others)

- Europe (Germany, France, United Kingdom, Italy, Spain, Russia, Others)

- Latin America (Brazil, Mexico, Others)

- Middle East and Africa

Note: If you require specific details, data, or insights that are not currently included in the scope of this report, we are happy to accommodate your request. As part of our customization service, we will gather and provide the additional information you need, tailored to your specific requirements. Please let us know your exact needs, and we will ensure the report is updated accordingly to meet your expectations.

About Us:

IMARC Group is a global management consulting firm that helps the world’s most ambitious changemakers to create a lasting impact. The company provide a comprehensive suite of market entry and expansion services. IMARC offerings include thorough market assessment, feasibility studies, company incorporation assistance, factory setup support, regulatory approvals and licensing navigation, branding, marketing and sales strategies, competitive landscape and benchmarking analyses, pricing and cost research, and procurement research.

Contact Us:

IMARC Group

134 N 4th St. Brooklyn, NY 11249, USA

Email: sales@imarcgroup.com

Tel No:(D) +91 120 433 0800

United States: +1-631-791-1145

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Oyunlar

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Other

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness