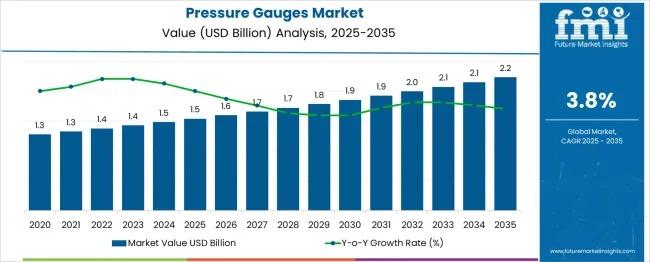

Pressure Gauges Market to Surpass USD 2.2 billion by 2035

The global Pressure Gauges Market is entering a transformative decade, with demand intensifying across manufacturing, energy, and process industries that rely on precise pressure monitoring for operational safety and efficiency. Valued at USD 1.5 billion in 2025, the market is projected to reach USD 2.2 billion by 2035, growing at a CAGR of 3.8%. The industry’s upward trajectory is underpinned by the adoption of digital gauges, rising automation, and increased investment in predictive maintenance technologies.

Subscribe for Year-Round Insights → Stay ahead with quarterly and annual data updates

https://www.futuremarketinsights.com/reports/sample/rep-gb-23337

From 2025 to 2030, the market is expected to expand from USD 1.5 billion to USD 1.9 billion, reflecting steady adoption across sectors such as oil & gas, pharmaceuticals, water treatment, and power generation. Growing emphasis on safety compliance, quality control, and accuracy in pressure measurement continues to reinforce the importance of both mechanical and digital gauges. Digital gauges—expected to hold 61% market share in 2025—remain preferred for their real-time monitoring, compatibility with IoT platforms, and ability to support predictive maintenance strategies.

Year-on-year analysis shows progressive market expansion, with values reaching USD 1.6 billion in 2026, USD 1.7 billion in 2027, and USD 1.8 billion in 2029. The increasing integration of wireless connectivity, improved durability, and enhanced calibration capabilities further strengthens manufacturer and end-user confidence in modern gauge technologies. Investments in energy infrastructure, coupled with industrial modernization across emerging economies, serve as strong catalysts for long-term adoption.

Why the Pressure Gauges Market Is Growing

The growth of the pressure gauges market is closely tied to heightened requirements for accurate monitoring in safety-critical applications. Industries such as oil and gas depend on robust mechanical gauges for drilling, refining, and pipeline operations, while manufacturing facilities rely heavily on digital gauges for real-time data acquisition. Regulatory expansion and heightened safety protocols worldwide are accelerating adoption across utility plants, chemical facilities, and water treatment operations.

Additionally, stainless steel gauges—projected to lead with a 43% market share—are increasingly preferred due to their corrosion resistance and suitability for harsh environments. The rise of Industry 4.0 and smart factory initiatives is pushing manufacturers to invest in connected, cloud-integrated gauge solutions that provide continuous visibility into process performance.

Key Segmental Insights

Product Type:

Digital pressure gauges dominate due to precision, durability, and IoT compatibility. These instruments now offer multi-unit measurements, advanced diagnostics, and seamless integration with plant automation systems.

Technology:

Bourdon tube gauges retain strong demand—holding 36% market share—due to their reliability, cost-effectiveness, and independence from power sources, making them essential for legacy systems and outdoor installations.

Material:

Stainless steel continues to gain momentum across petrochemical, pharmaceutical, and marine applications where gauges must withstand corrosive environments and extreme operating conditions.

Regional Growth Trends

Asia-Pacific leads global growth, with China expanding at 5.1% CAGR and India at 4.8%, fueled by rapid industrialization, infrastructure investments, and increasing adoption of digital instrumentation.

Europe demonstrates strong demand due to advanced automation requirements, with Germany (4.4% CAGR) prioritizing smart gauges integrated into Industry 4.0 environments.

North America, led by the United States at 3.2% CAGR, remains a mature yet lucrative market driven by the modernization of oil & gas infrastructure and increasing use of predictive analytics.

Opportunities and Market Drivers

- Growing industrial automation and focus on predictive maintenance

- High adoption of wireless and compact pressure gauges

- Demand for robust gauges in oil refineries, chemical plants, and pharmaceuticals

- Rising investments in smart sensors and SCADA-integrated systems

Market Challenges

Despite strong potential, challenges persist—including high calibration costs, competition from electronic sensors, and lack of standardization in certain regions. The need for cost-effective, high-accuracy solutions continues to influence innovation strategies across the supply chain.

Competitive Landscape

Global leaders such as WIKA Instruments, Emerson, Honeywell, Ametek, Omega Engineering, and Fluke Corporation are shaping the industry with advanced digital and hybrid solutions tailored for critical environments. Emerging players including Badotherm, Circor, Dwyer, Winters Instruments, and Kobold Instruments are expanding their footprint through specialized gauges, competitive pricing, and enhanced material-focused innovations.

As industries intensify their focus on safety, automation, and predictive maintenance, the pressure gauges market is set to experience consistent technological advancement over the next decade.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- الألعاب

- Gardening

- Health

- الرئيسية

- Literature

- Music

- Networking

- أخرى

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness