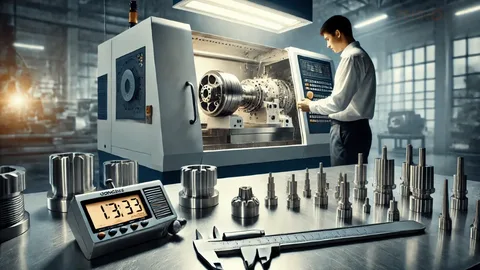

Industry-Leading Professional Precision Engineering Services for Precision Parts

In today’s fast-paced industrial landscape, the demand for precision, efficiency, and reliability has never been higher. Businesses across sectors, from aerospace to medical devices, increasingly rely on advanced manufacturing processes to deliver components that meet stringent standards. At the heart of this technological evolution are professional precision engineering services, which ensure that every part, regardless of complexity, is crafted with unmatched accuracy. These services leverage cutting-edge machinery, expert knowledge, and meticulous quality control to produce parts that not only meet but often exceed client expectations.

By adopting a holistic approach, professional precision engineering services offer businesses a competitive edge in delivering high-quality products on time. Precision parts, by their very nature, require expertise, advanced technology, and stringent adherence to tolerances. With the support of professional precision engineering services, companies can streamline production, reduce errors, and maintain consistency across batches, enabling them to meet demanding industry standards and regulatory requirements seamlessly.

Advanced Technology in Precision Engineering

One of the hallmarks of professional precision engineering services is the integration of advanced technology into the manufacturing process. Modern precision engineering relies on Computer Numerical Control (CNC) machines, 3D printing, and automated systems to achieve the highest levels of accuracy. These technologies allow engineers to produce intricate parts with tight tolerances, ensuring consistency and reliability even in high-volume production. By using sophisticated machinery, businesses can also minimize material waste and reduce production time, resulting in significant cost savings.

Additionally, the adoption of cutting-edge technology extends beyond machinery to include computer-aided design (CAD) and computer-aided manufacturing (CAM) software. These tools enable engineers to simulate, test, and optimize parts before actual production begins. With such precision planning, companies benefit from faster prototyping, lower risk of errors, and a more streamlined workflow. This technological advantage makes professional precision engineering services indispensable for industries that require exacting standards, such as aerospace, automotive, and medical equipment manufacturing.

Expertise and Skilled Workforce

Technology alone cannot guarantee perfection in precision parts production; expertise and human skill are equally critical. Professional precision engineering services are staffed with highly trained engineers, machinists, and technicians who bring years of experience to the table. Their deep understanding of materials, mechanical properties, and production processes allows them to solve complex engineering challenges and deliver parts that meet stringent specifications. This combination of skill and knowledge ensures that each component is not only accurate but also durable and reliable under demanding operational conditions.

Furthermore, continuous training and professional development are central to maintaining excellence in professional precision engineering services. As new materials, processes, and technologies emerge, skilled engineers remain at the forefront of innovation, ready to apply advanced techniques to client projects. This commitment to expertise ensures that businesses partnering with precision engineering services can consistently achieve high-quality results, reduce rework, and maintain operational efficiency across their production lines.

Quality Assurance and Regulatory Compliance

The production of precision parts requires meticulous quality assurance to ensure that each component meets the highest standards. Professional precision engineering services implement comprehensive quality control protocols, including dimensional inspection, material analysis, and functional testing. These rigorous checks are conducted at multiple stages of the production process, from initial design through final assembly, ensuring that every part conforms to exact specifications. By maintaining strict quality assurance, companies can reduce defects, avoid costly recalls, and enhance overall product reliability.

In addition to internal quality checks, many professional precision engineering services are certified to comply with international standards, such as ISO 9001, AS9100 for aerospace, or ISO 13485 for medical devices. Regulatory compliance is critical for industries where safety, performance, and traceability are paramount. Partnering with a service provider that adheres to these stringent standards provides clients with confidence that their precision parts are not only engineered for performance but also meet legal and safety requirements, reinforcing trust and long-term business relationships.

Custom Solutions for Complex Requirements

Every industry has unique requirements that demand tailored engineering solutions. Professional precision engineering services excel in providing customized solutions for complex projects that off-the-shelf components cannot address. Whether designing specialized aerospace fittings, intricate medical devices, or high-performance automotive parts, precision engineers work closely with clients to develop parts that meet exact functional and dimensional criteria. This bespoke approach ensures that the final product integrates seamlessly into the intended application, enhancing performance and longevity.

Custom precision engineering also involves material selection, surface treatments, and post-processing techniques that enhance part functionality. Engineers can choose from a wide range of metals, alloys, and polymers to optimize strength, corrosion resistance, and durability. By offering such tailored solutions, professional precision engineering services empower businesses to innovate, achieve superior performance, and stay ahead in highly competitive markets where standard solutions fall short.

Cost-Effectiveness and Operational Efficiency

While precision engineering might seem expensive at first glance, professional precision engineering services actually deliver long-term cost-effectiveness. By reducing material waste, minimizing rework, and improving production accuracy, businesses can achieve significant savings over time. The initial investment in advanced machinery, skilled labor, and quality assurance translates into lower defect rates, fewer production delays, and more predictable project timelines, ultimately reducing overall operational costs.

Moreover, professional precision engineering services enhance operational efficiency by streamlining the production workflow. Automated processes, efficient project management, and strategic planning enable faster turnaround times without compromising quality. Companies can respond quickly to market demands, meet tight deadlines, and maintain consistent product quality, all of which contribute to enhanced customer satisfaction and business growth. By integrating precision engineering services into their operations, businesses can enjoy both technical excellence and economic efficiency simultaneously.

Conclusion

The demand for high-quality precision parts continues to rise across industries, making professional precision engineering services more critical than ever. By combining advanced technology, skilled expertise, rigorous quality control, and customized solutions, these services ensure that every component meets the highest standards of accuracy and reliability. Businesses that invest in professional precision engineering services not only benefit from superior products but also gain a competitive edge in their respective industries.

Ultimately, partnering with industry-leading precision engineering providers allows companies to innovate, maintain operational efficiency, and achieve cost-effective production while adhering to strict regulatory standards. From aerospace to medical devices, professional precision engineering services form the backbone of modern manufacturing, delivering parts that are precise, reliable, and tailored to meet the unique demands of today’s complex industrial landscape.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Juegos

- Gardening

- Health

- Inicio

- Literature

- Music

- Networking

- Otro

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness