Industrial Fastener Manufacturers Count On Reliable Swiss Machining Services Daily

Sometimes the whole manufacturing world feels like it runs on tiny parts.

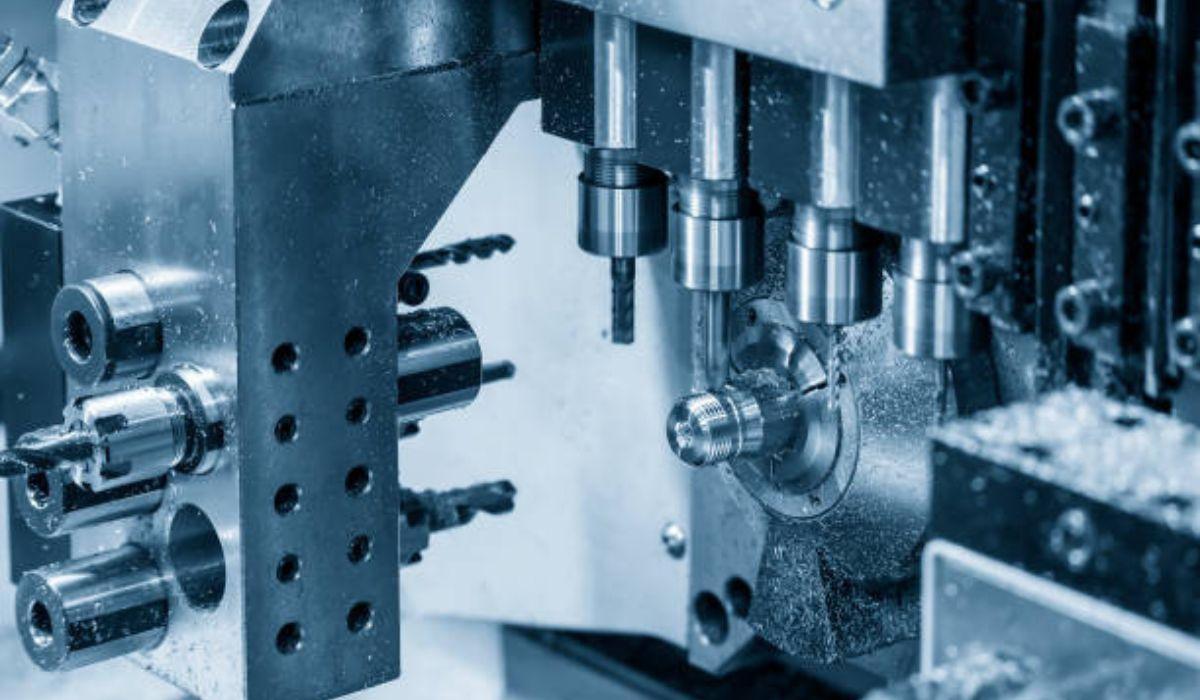

Small things. Little components that don’t look like much but you need them perfect, every time. And that’s exactly where things like swiss machining start to pull their weight. It’s not fancy talk. It’s just the truth in most shops I’ve walked through.

When people ask why shops keep leaning on this process, I tell them straight. Because it works. Because it keeps tolerances tight, and because industrial fastener manufacturers don’t really get the luxury of “close enough.” Not in 2025. Not anymore. The bar is too damn high.

Why This Level of Precision Even Matters Now

Look—nobody’s building a rocket with sloppy tolerances.

Even basic equipment needs real accuracy. So that’s why swiss machining has become one of those not-optional tools. You bring it in when you want things done right.

Or when you don’t want to babysit a part for six hours hoping it comes out usable.

And I’ve seen the same story unfold in shop after shop.

Industrial fastener manufacturers keep ramping up orders with tighter specs, smaller diameters, weird materials that used to scare machinists off. But swiss machines? They chew through it anyway. They don’t complain. They don’t drift as much. And that consistency is worth more than people admit.

Swiss Machining in the Real World (Not the Brochure Version)

Here’s the part most folks don’t say out loud.

Swiss machining isn’t just about fancy numbers or some brochure showing 0.0002 tolerance. It’s more about reliability. You can run long parts, smaller workpieces, tiny pins, threaded inserts, fastener bodies––whatever falls on the table that day.

And because the guide bushing supports the material so tight, the thing just doesn’t chatter.

That alone saves you hours.

Think about it from the angle of industrial fastener manufacturers.

They deal with parts that must withstand stress, torque, vibration, temperature swings. If the part’s off by even a little, they’re in trouble. That’s why the swiss setup becomes almost the default choice for them. Not hype, just common sense.

The Demands Fastener Companies Bring to the Table

Most folks don’t realize how ruthless the fastener world is.

You’d think a bolt is a bolt. A screw is a screw. But no.

Industrial fastener manufacturers push insane volume, and they expect perfect repeatability. It’s a weird blend of mass production and precision manufacturing all at once.

A few things they need (and demand):

— Dimensional stability across thousands of pieces

— Surface finishes that don’t look like they were dragged across concrete

— Material versatility

— Turnaround times that don’t drag on for months

That’s where swiss machining steps in again.

It can handle brass, stainless, titanium, high-nickel stuff—materials that behave badly in older equipment. And the cycle times? Shorter. Sharper. More predictable.

Where Swiss Machining Actually Saves the Day

You want a real explanation?

Fine. Here’s the simple version. Swiss machining brings together speed + stability + supported cutting. The stock stays rigid. Tooling sits close. Deflection drops way down. And that’s exactly what industrial fastener manufacturers keep banking on.

Imagine trying to machine a 2 mm diameter fastener pin on an old lathe.

It’ll whip, bend, vibrate, maybe snap.

But on a swiss machine? Dead straight. Clean. Done.

I’ve seen components run overnight with barely any fight.

The machines keep grinding through parts like it’s nothing. That’s the kind of performance that builds trust.

Material Challenges That Don’t Scare Swiss Machines

You toss these machines tough alloys, and they barely blink.

Medical-grade stainless. Aerospace titanium. Exotic alloys that really should come with warning labels. Swiss machining just handles most of it. Not always pretty… but it gets the job done.

Industrial fastener manufacturers rely on that. Because their clients (aerospace, automotive, heavy equipment makers) aren’t exactly forgiving.

If a part fails in the field, someone’s paying for it. Probably a lot.

So swiss shops have become the quiet backbone behind so many of these fastener operations. Running pins, sleeves, precision bolts, miniature shafts.

Some as small as the threads on your glasses. Some tougher than any hobby machinist would want to deal with.

The Future of Fastener Production Runs Through Swiss Machines

I’ll tell you something blunt.

The shops that survive the next decade are the ones that adapt faster than the rest. And the ones investing in swiss machining today? They’re already miles ahead.

Industrial fastener manufacturers are shifting toward automation, lights-out runs, smarter QC, tighter reporting. Swiss machines fit perfectly into that world.

Small footprint. Multi-axis setups. High accuracy.

And let’s be honest—they’re just workhorses.

This tech isn’t going anywhere.

If anything, it’ll own more of the fastener industry than it already does.

Final Thoughts on Why This Process Isn’t Optional Anymore

So yeah, swiss machining gets a lot of hype.

But for once, the hype is deserved.

It’s accurate. It’s efficient. It’s stable even when you’re cutting toothpick-thin parts that most machines would destroy.

And for industrial fastener manufacturers, that reliability is gold.

Not fluff. Not buzzwords. Just parts that come out right the first time. And the fiftieth time. And the thousandth.

If you’re a shop owner thinking you can keep up without swiss capability… good luck. The industry’s changing whether anyone likes it or not.

FAQs

Q1: Why is swiss machining becoming so widely used now?

Because tolerances keep getting tighter and customers want nearly perfect parts. The process handles small, long, complex components with far less risk.

Q2: How does swiss machining help industrial fastener manufacturers specifically?

It delivers accuracy, consistency, higher volume capability, and better control over thin or delicate fastener parts.

Q3: Can swiss machines handle tough or exotic materials?

Yes, most modern setups run stainless, titanium, and high-strength alloys without much trouble.

Q4: Is swiss machining worth the investment for small shops?

If you deal with small-diameter components, long parts, or recurring precision work… yeah, it’s worth every bit.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Games

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Other

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness