Never Play Roulette Again with Osk SPC Flooring Factory

For anyone who has ever tried to expedite a home improvement project, encountering unexpected delays in material sourcing can be a confusing and aggravating experience. The heart of this issue often lies in the operational heartbeat of an SPC Flooring Factory. The modern manufacturing landscape is built on economies of scale, where efficiency is paramount. This naturally leads to a production prioritization model that favors large-quantity orders, leaving smaller batches and specialty items to be produced during operational lulls or from surplus material. This "batch roulette" system is a standard industry practice, but for the individual consumer, it can feel like their project is being overlooked in favor of bigger, more lucrative clients.

The reasoning behind this model is rooted in pure logistics and cost-effectiveness. Setting up production lines for a specific type of flooring involves precise calibration of machinery, sourcing and preparing a specific blend of raw materials, and allocating labor. Each time the factory switches from producing one style to another, it incurs costs and loses productive time. Therefore, to maintain profitability and operational smoothness, the most logical step is to minimize these changeovers. This results in extended production runs of high-demand products, fulfilling contracts for large-scale commercial developments or major retail distribution networks. The production of limited-run colors or small orders is then dependent on the gaps between these large batches, making their availability sporadic and less predictable.

This reality directly impacts the consumer experience. A homeowner might have a clear vision for their space, select a perfect sample, and be ready to proceed, only to be told that their chosen flooring is temporarily out of stock with no firm restock date. This isn't a reflection of poor service from their retailer, but rather a ripple effect from the factory's production schedule. Their project is waiting for a large enough quantity of orders for that specific product to justify a dedicated production run, or for leftover material to become available. This disconnect between the manufacturing process and the end-user's immediate needs is a classic pain point in the industry.

Yet, a new wave of customer-centric manufacturing is beginning to challenge this status quo. Forward-thinking operations are developing more agile approaches, recognizing that the market is built on both large and small projects. This can involve employing advanced forecasting to anticipate demand for popular residential products or allocating a portion of production capacity specifically for fulfilling smaller, direct orders. This shift requires a sophisticated coordination of supply chain and inventory management, but it successfully bridges the gap between industrial efficiency and individual customer satisfaction.

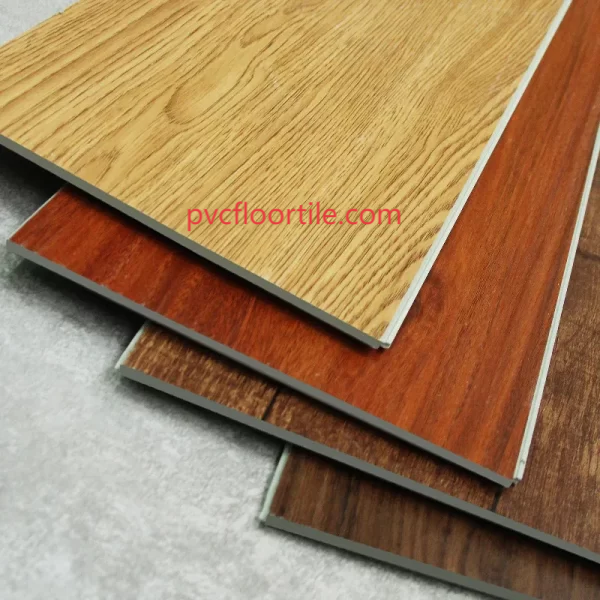

At Pvcfloortile, we are proud to be at the forefront of this customer-focused approach. We operate a sophisticated SPC Flooring Factory but have rejected the notion that small orders must be subject to endless waiting. We have streamlined our processes to accommodate a diverse range of project sizes without compromising on efficiency or quality. Our goal is to provide dependable service and clear timelines for every client. Partner with Pvcfloortile for a seamless sourcing experience that gets your project started on time.Click https://www.pvcfloortile.com/product/ to reading more information.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Игры

- Gardening

- Health

- Главная

- Literature

- Music

- Networking

- Другое

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness