Nante Solutions For Reliable Industrial Concealed Socket Integration

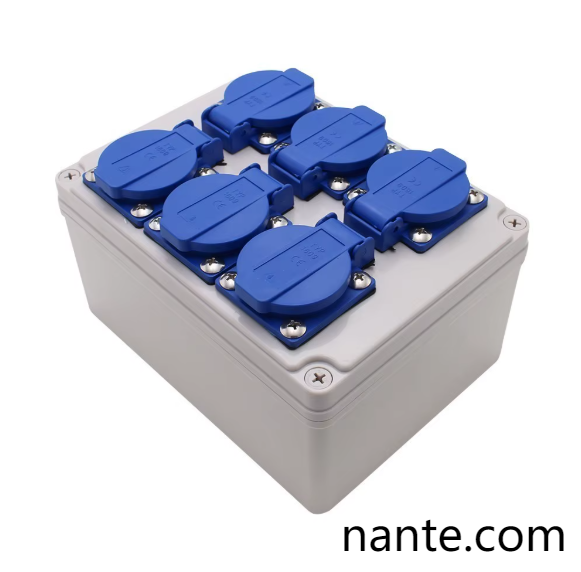

In modern production settings where space and safety matter, choosing the right Industrial concealed socket can make a tangible difference. Hidden outlets fit flush into machine frames and service islands, reducing exposed wiring and lowering the chance of accidental contact during busy shifts. Facility managers, safety officers, and system integrators increasingly look for compact power solutions that support tidy layouts while meeting operational demands.

Start by assessing where power is needed and how often devices will connect. Consider whether the unit will feed fixed equipment, mobile tools, or occasional test gear. Each application places different demands on contact life, terminal capacity, and mechanical robustness. For instance, outlets that see frequent mating should use reinforced housings and secure locking devices to remain reliable as crews plug and unplug over long production cycles.

Ingress protection and material choice matter in harsh environments. A sealed enclosure resists dust and water while corrosion resistant finishes maintain appearance where washdown or high humidity occurs. Selecting proper sealing helps keep insulation secure and prevents moisture driven faults. Look for units that combine tight gaskets with corrosion resistant fixings so the assembly stays serviceable despite routine cleaning or accidental splashes.

Thermal handling and current capacity influence which model to buy. Compact sockets concentrate heat when loads run long. Choose versions that offer generous conductor space and good thermal paths so installations do not develop hot spots. In some factories, optional monitoring modules report temperature trends back to the control system, helping technicians spot connections that require attention before trips occur.

Access and maintenance should be part of the specification. Recessed frames that allow front access to terminations reduce the need for panel removal during inspections. Quick release covers and captive fasteners speed routine checks and simplify spare part exchanges. When specifying, verify that terminal types accept the conductor styles used on site and that replacement modules are available through established distribution channels.

Compatibility with control and protection gear matters when outlets serve powered tools or charging stations. Select models that allow integration with circuit breakers, residual current devices, and optional sensing modules inside the same enclosure. This arrangement reduces external wiring and keeps protective devices close to the load, improving fault clearing times and reducing the chance of nuisance trips.

Ergonomics and operator interaction are often overlooked. Consider covers and latches that operate easily when workers wear gloves or handle tools. Clear markings and captive labels help crews identify circuits quickly during changeovers. Where outlets support portable instruments, including strain reliefs and cord guides reduces connector stress and prevents accidental disconnection.

Installation logistics also affect long term value. Prewired assemblies that fit standard cutouts reduce field labor and improve consistency across multiple cells. If a project includes several machines, using the same socket family simplifies stocking of spares and speeds repairs. Vendors who publish installation templates and wiring diagrams supply installers with the documentation inspectors want to see.

When evaluating vendors, balance product features with support. Responsive technical assistance, straightforward accessory lists, and available training shorten commissioning times. Manufacturers that provide clear integration notes make it easier to include concealed outlets in safety audits and automation plans. A trusted supplier also simplifies warranty administrative steps if problems ever arise.

Upgrading current panels to include concealed outlets can tidy work areas and reduce trip hazards associated with extension cords. Small investments in stronger connectors and better sealing often translate into fewer interruptions and lower maintenance burdens. Engineers who plan for modular growth will find it easier to adapt layouts as production needs change.

For those interested in models, accessories, and installation guidance, product families and technical resources can be reviewed at www.nante.com. The site contains specification sheets, mounting recommendations, and contact paths for technical support. These resources help engineers and procurement teams match a concealed socket selection to site requirements and safety procedures so installations meet both performance and regulatory expectations.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Παιχνίδια

- Gardening

- Health

- Κεντρική Σελίδα

- Literature

- Music

- Networking

- άλλο

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness