The Role of Perforation in Well Completion: Methods and Best Practices

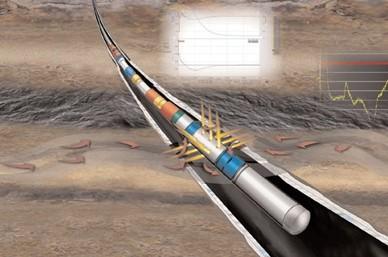

Well completion is a critical phase in oil and gas development, bridging the gap between drilling and production. Among the most essential aspects of completion is perforation, the process of creating channels through the casing or liner into the reservoir to allow hydrocarbons to flow. Proper perforation is vital to maximize production efficiency and ensure long-term well integrity.

Methods of Perforation

There are several perforation techniques commonly used in the industry:

Conventional Perforating Guns – This method uses explosive charges arranged in a gun to perforate the casing and reservoir rock. It is highly effective in both vertical and horizontal wells and provides predictable penetration depth.

Hydraulic Jet Perforation – Instead of explosives, high-pressure fluid jets are used to create perforations. This method is especially useful in sensitive formations where minimizing formation damage is critical.

Underbalanced Perforation – Performed when the wellbore pressure is intentionally kept below the formation pressure. This technique reduces the risk of formation damage and enhances the inflow of hydrocarbons.

Coiled Tubing Perforation – Using coiled tubing allows for precise placement of perforations and can be performed without pulling the tubing out of the well. It’s particularly useful for multi-zone completions.

Best Practices for Effective Perforation

Accurate Depth Control: Misaligned perforations can lead to uneven production or bypassed pay zones. Modern measurement tools and perforation depth logs ensure precise targeting.

Optimal Charge Selection: Charges must be chosen based on formation properties and well conditions. The penetration depth, hole diameter, and orientation all influence production rates.

Minimizing Formation Damage: Techniques such as underbalanced perforation or using specially designed charges help maintain reservoir permeability and prevent sand migration.

Zonal Isolation: Perforation should be coordinated with packers or other completion tools to ensure that fluids from different zones do not mix.

Monitoring and Evaluation: After perforation, well testing and logging help assess perforation effectiveness, guiding stimulation treatments like acidizing or hydraulic fracturing.

Conclusion

Perforation is more than just creating holes in a casing; it is a strategic intervention that directly impacts well productivity, longevity, and safety. Employing the right method with careful planning and precision ensures efficient hydrocarbon flow while minimizing formation damage. By adhering to best practices, operators can maximize reservoir contact and optimize overall production, ultimately translating into higher recovery rates and reduced operational risks.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Games

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Other

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness