Specialty Polymers Market Trends, Growth, and Demand Forecast 2025-2033

Market Overview:

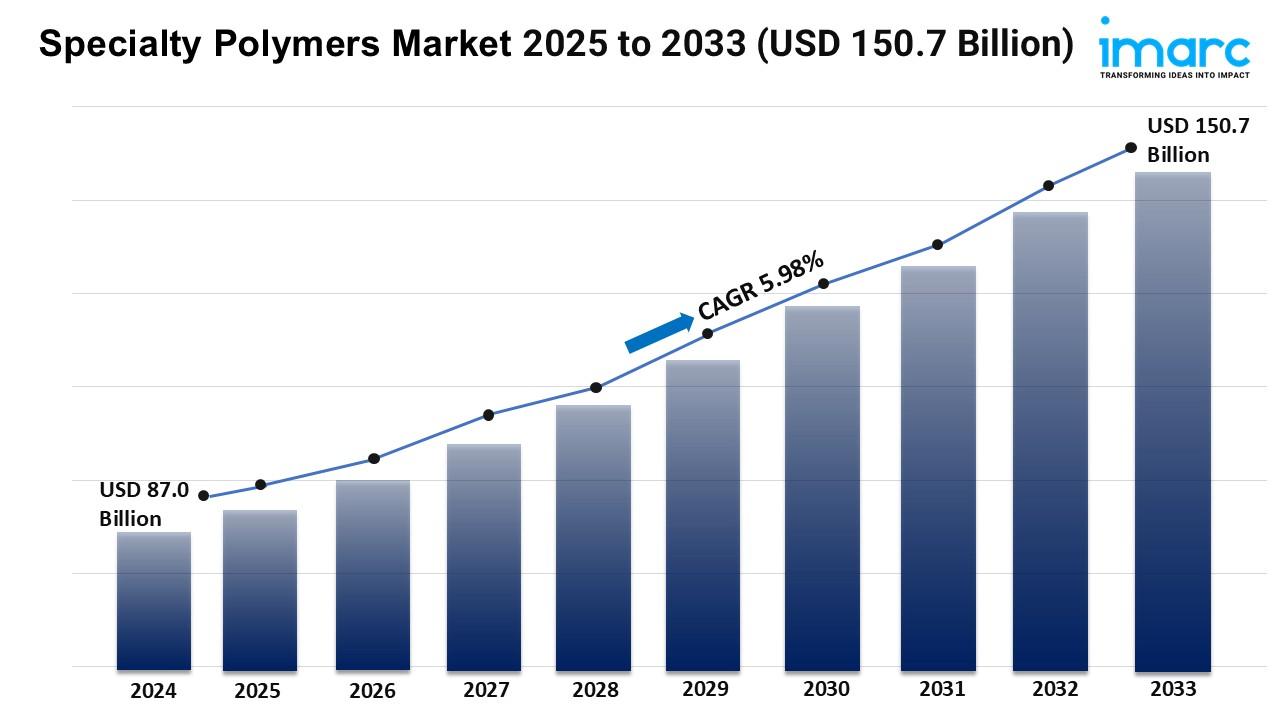

The specialty polymers market is experiencing rapid growth, driven by surging demand for lightweight materials in automotive and aerospace, booming electronics industry needs high-performance polymers, and construction sector’s appetite for durable, sustainable materials. According to IMARC Group's latest research publication, "Specialty Polymers Market: Global Industry Trends, Share, Size, Growth, Opportunity and Forecast 2025-2033", The global specialty polymers market size reached USD 87.0 Billion in 2024. Looking forward, IMARC Group expects the market to reach USD 150.7 Billion by 2033, exhibiting a growth rate (CAGR) of 5.98% during 2025-2033.

This detailed analysis primarily encompasses industry size, business trends, market share, key growth factors, and regional forecasts. The report offers a comprehensive overview and integrates research findings, market assessments, and data from different sources. It also includes pivotal market dynamics like drivers and challenges, while also highlighting growth opportunities, financial insights, technological improvements, emerging trends, and innovations. Besides this, the report provides regional market evaluation, along with a competitive landscape analysis.

Grab a sample PDF of this report: https://www.imarcgroup.com/specialty-polymers-market/requestsample

Our report includes:

- Market Dynamics

- Market Trends And Market Outlook

- Competitive Analysis

- Industry Segmentation

- Strategic Recommendations

Growth Factors in the Specialty Polymers Market

- Surging Demand for Lightweight Materials in Automotive and Aerospace:

The specialty polymers industry is booming because automakers and aerospace companies are obsessed with cutting weight to boost fuel efficiency and slash emissions. Specialty polymers like polyetheretherketone (PEEK) and polyphenylene sulfide (PPS) are replacing heavier metals, reducing vehicle weight by up to 10%. For instance, Toyota has used carbon fiber-reinforced polypropylene in concept vehicles to enhance performance. These materials also offer durability and corrosion resistance, perfect for tough environments. Government policies, like China’s push for 7 million electric vehicles annually, are fueling demand for lightweight components in EV batteries and aerospace parts. This drive for efficiency and sustainability is a massive win for specialty polymers, making them a go-to choice for manufacturers aiming to meet strict regulations and consumer expectations.

- Booming Electronics Industry Needs High-Performance Polymers:

The electronics world is leaning hard on specialty polymers for their stellar electrical insulation and thermal stability, crucial for today’s sleek, high-tech devices. Global electronics production by Japanese firms alone hit $285 billion recently, driving demand for materials like conducting polymers used in smartphone components and semiconductors. SABIC’s new ULTEM resin factory in Singapore is a prime example, catering to AI and telecom needs. These polymers enable smaller, more efficient gadgets, supporting the push for flexible electronics. As consumer appetite for advanced tech grows, manufacturers need materials that can handle extreme conditions without breaking a sweat. Specialty polymers fit the bill, offering reliability and performance, which is why they’re becoming indispensable in everything from wearables to cutting-edge AI hardware.

- Construction Sector’s Appetite for Durable, Sustainable Materials:

Construction is eating up specialty polymers thanks to their toughness, moisture resistance, and ability to withstand brutal weather. Global construction output is projected to hit $12.8 trillion soon, with Asia-Pacific, especially China and India, leading the charge. Specialty elastomers, for instance, are used in bridges and buildings for their flame resistance and structural strength. BASF recently expanded its Ultrason thermoplastic production in South Korea to meet this demand. India’s “Make in India” campaign has also sparked foreign investment, boosting local production of high-performance materials. These polymers are a game-changer for building reliable, long-lasting structures that avoid early repairs. As urbanization ramps up, the need for sustainable, durable materials in infrastructure projects is pushing specialty polymers to the forefront of construction innovation.

Key Trends in the Specialty Polymers Market

- Rise of Bio-Based and Biodegradable Polymers:

Sustainability is shaking up the specialty polymers market, with bio-based and biodegradable options stealing the spotlight. These polymers, made from renewable sources like sugarcane or starch, cut carbon emissions and align with global eco-goals. For example, ethylene from sugarcane is used to make polyethylene, while starch creates polylactic acid (PLA). SABIC’s TRUCIRCLE portfolio offers circular polymers for sustainable packaging, meeting consumer demand for greener products. In packaging, biopolymers are prized for compostability, reducing plastic waste. They’re also popping up in automotive and textiles, helping manufacturers meet strict environmental regulations. As governments and consumers push for eco-friendly solutions, bio-based polymers are becoming a hot trend, driving innovation and opening new markets for specialty polymer producers.

- Customization for Niche Applications:

Specialty polymers are getting a major glow-up with customization for super-specific applications. Instead of one-size-fits-all, companies are tailoring polymers to meet unique needs, like biocompatibility for medical devices or flame resistance for aerospace parts. For instance, PEEK is used in medical implants for its chemical inertness, with global demand for PEEK in orthopedics surging. Covestro’s focus on custom solutions and technical support has strengthened its market lead, offering clients polymers fine-tuned for performance. This trend is huge in electronics, where polymers enable flexible displays, and in automotive, where they boost EV battery efficiency. Customization lets manufacturers stand out in competitive industries, delivering high-performance materials that solve real-world problems and fuel growth in specialized sectors.

- 3D Printing Revolutionizing Polymer Use:

3D printing is flipping the script on how specialty polymers are used, opening doors to mind-blowing innovation. These polymers, like high-strength thermoplastics, are perfect for creating complex, lightweight parts in industries from aerospace to healthcare. For example, 3D-printed PEEK implants are transforming orthopedic surgery with their precision and biocompatibility. The global 3D printing market for polymers is seeing massive uptake, with companies like Arkema developing specialized resins for additive manufacturing. This tech slashes production costs and waste, letting firms prototype and produce custom components faster. In automotive, 3D-printed polymer parts are cutting vehicle weight, boosting efficiency. As 3D printing tech gets cheaper and more accessible, it’s sparking a wave of creativity, making specialty polymers a key player in next-gen manufacturing.

Leading Companies Operating in the Global Specialty Polymers Industry:

- 3M Company

- A. Schulman Inc. (LyondellBasell Industries N.V.)

- Arkema S.A.

- Ashland Inc.

- Avient Corporation

- BASF SE

- Croda International Plc

- Dow Inc.

- Evonik Industries AG

- Koninklijke DSM N.V.

- Solvay S.A.

- Specialty Polymers Inc. (The Sherwin-Williams Company)

Specialty Polymers Market Report Segmentation:

Breakup By Product Type:

- Specialty Elastomers

- Fluoroelastomers

- Fluorosilicone Rubber

- Liquid Silicone Rubber

- Natural Rubber

- Others

- Specialty Composites

- Particle Reinforced Composites

- Fiber Reinforced Composites

- Structural Composites

- Specialty Thermoplastics

- Polyolefins

- Polyimides

- Vinyl Polymer

- Polyphenols

- Others

- Specialty Thermosets

- Epoxy

- Polyester

- Vinyl Ester

- Polyimides

- Others

- Others

Specialty elastomers represent the biggest segment due to their ability to perform under harsh conditions and their versatility in various manufacturing processes.

Breakup By End Use Industry:

- Automotive and Transportation

- Consumer Goods

- Building and Construction

- Coatings, Adhesives, and Sealants

- Electrical and Electronics

- Healthcare

- Others

Automotive and transportation account for the majority of the market share because of the increasing demand for lightweight, high-performance polymers that improve fuel efficiency, safety, and durability in vehicles and transportation systems.

Breakup By Region:

- North America (United States, Canada)

- Asia Pacific (China, Japan, India, South Korea, Australia, Indonesia, Others)

- Europe (Germany, France, United Kingdom, Italy, Spain, Russia, Others)

- Latin America (Brazil, Mexico, Others)

- Middle East and Africa

Asia Pacific enjoys the leading position in the market owing to the thriving automotive, electronics, and manufacturing sectors, increasing investments in advanced technologies, and rising demand for high-performance materials.

Research Methodology:

The report employs a comprehensive research methodology, combining primary and secondary data sources to validate findings. It includes market assessments, surveys, expert opinions, and data triangulation techniques to ensure accuracy and reliability.

Note: If you require specific details, data, or insights that are not currently included in the scope of this report, we are happy to accommodate your request. As part of our customization service, we will gather and provide the additional information you need, tailored to your specific requirements. Please let us know your exact needs, and we will ensure the report is updated accordingly to meet your expectations.

About Us:

IMARC Group is a global management consulting firm that helps the world’s most ambitious changemakers to create a lasting impact. The company provide a comprehensive suite of market entry and expansion services. IMARC offerings include thorough market assessment, feasibility studies, company incorporation assistance, factory setup support, regulatory approvals and licensing navigation, branding, marketing and sales strategies, competitive landscape and benchmarking analyses, pricing and cost research, and procurement research.

Contact Us:

IMARC Group

134 N 4th St. Brooklyn, NY 11249, USA

Email: sales@imarcgroup.com

Tel No:(D) +91 120 433 0800

United States: +1-201971-6302

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Giochi

- Gardening

- Health

- Home

- Literature

- Musica

- Networking

- Altre informazioni

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness