How Rotary Lobe Pumps Are Designed for Easy Maintenance

Rotary lobe pumps play a crucial role in various industries, particularly where precise fluid handling is required. These pumps are widely used in sectors such as food processing, pharmaceuticals, chemical production, and wastewater treatment. As industries continue to rely on these pumps for efficient fluid transfer, the demand for pumps that are easy to maintain has risen significantly. In this article, we will explore the design features of rotary lobe pumps that contribute to their ease of maintenance, as well as the benefits they offer to businesses in maintaining operational efficiency.

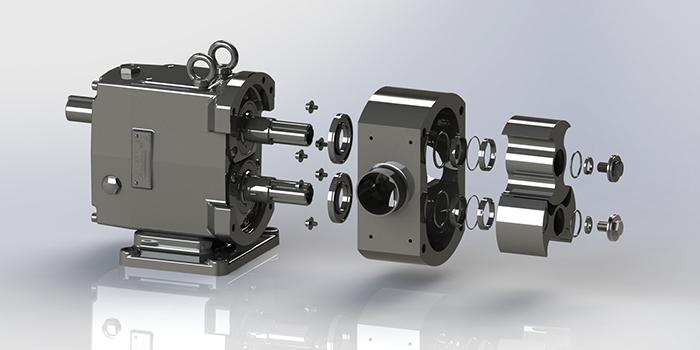

What is a Rotary Lobe Pump?

A rotary Lobe Pump is a positive displacement pump that uses two or more lobes to move liquids or slurries. These lobes rotate in a cylindrical casing, creating cavities that expand and contract to push the fluid from the inlet to the outlet. The design of the rotary lobe pump makes it suitable for handling viscous, shear-sensitive, or abrasive liquids.

Why is Easy Maintenance Essential for Rotary Lobe Pumps?

Maintenance is an inevitable part of any industrial operation, and rotary lobe pumps are no exception. Regular maintenance ensures that pumps continue to operate at their best, reducing the likelihood of costly downtime and unexpected repairs. The ease of maintenance in a rotary lobe pump is a key feature that helps businesses reduce their total cost of ownership, extend pump lifespan, and improve overall performance.

Key Features of Rotary Lobe Pumps That Make Maintenance Easy

1. Quick Disassembly for Cleaning and Inspection

One of the standout features of rotary lobe pumps is their design, which allows for quick and easy disassembly. This ease of disassembly is essential for industries such as food processing, where cleaning is crucial to maintain hygiene standards. Ace Lobe Pumps, a leading manufacturer in the field, designs pumps that can be easily taken apart without the need for specialized tools. This reduces downtime and ensures that cleaning and inspection processes can be performed swiftly.

2. Minimal Wearing Parts

Another maintenance-friendly feature of rotary lobe pumps is the limited number of wearing parts. Unlike other types of pumps, which may have multiple components prone to wear and tear, rotary lobe pumps have fewer parts that need regular replacement. The rotary lobes, typically made of durable materials like stainless steel or rubber, are designed to last for extended periods without significant wear. This reduces the frequency of replacements and the associated costs.

3. Self-Priming Capabilities

Rotary lobe pumps are often self-priming, meaning they can start without needing to be manually primed. This reduces the need for manual intervention during the pump’s operation, making it easier for operators to keep the system running smoothly without frequent maintenance. This feature is particularly beneficial in applications where the pump needs to handle viscous fluids or slurries.

4. Sealing Systems Designed for Durability

The sealing system in a rotary lobe pump is one of its most crucial components for preventing leaks and maintaining operational efficiency. The seals used in Ace Lobe Pumps are designed for long-lasting performance, with minimal wear over time. Advanced sealing technology not only ensures the pump is leak-proof but also simplifies the maintenance process by reducing the frequency of seal replacements.

5. Easy Access to Key Components

Routine maintenance tasks often require access to internal components such as the bearings, seals, and rotors. Ace Lobe Pumps are designed with easy access to these parts, allowing for quick inspections and replacements. Whether you need to replace the lobes or inspect the bearings, you can access the parts with minimal disassembly, saving both time and labor costs.

Benefits of Easy Maintenance in Rotary Lobe Pumps

1. Reduced Downtime

When pumps are easy to maintain, the amount of time spent on repairs and routine servicing is significantly reduced. Shorter maintenance times mean less downtime, leading to higher productivity. Businesses that use rotary lobe pumps can keep operations running without significant interruptions, improving overall efficiency.

2. Cost-Effectiveness

Reducing the time and effort required for maintenance lowers the operational costs associated with the pump. Fewer labor hours are needed for maintenance tasks, and businesses can extend the life of their pumps by using high-quality materials designed for durability. This cost-effectiveness makes Ace Lobe Pumps a wise investment for any business in need of reliable fluid transfer.

3. Extended Pump Lifespan

Regular maintenance ensures that pumps continue to operate at their peak performance. With easy-to-maintain features, such as quick disassembly and durable seals, Ace Lobe Pumps can last for many years without the need for major repairs. A longer lifespan means fewer replacements, saving businesses money in the long run.

4. Improved Performance

When a pump is properly maintained, it operates more efficiently, leading to consistent performance. Easy maintenance allows operators to keep the pump clean and well-lubricated, preventing issues such as clogging or overheating that could reduce its performance. A well-maintained rotary lobe pump delivers higher throughput and better efficiency.

Choosing the Right Rotary Lobe Pump for Easy Maintenance

When selecting a rotary lobe pump, it is important to choose a model designed for ease of maintenance. Some pumps are more complex and require specialized knowledge to maintain, which can lead to higher service costs. On the other hand, pumps designed with user-friendly features, like those offered by Ace Lobe Pumps, are simpler to maintain and more cost-effective in the long term.

1. Material Selection

Selecting the right materials is key to reducing wear and tear on the pump. Ace Lobe Pumps uses high-quality materials such as stainless steel, which offers excellent corrosion resistance and strength. This material choice helps reduce maintenance frequency and keeps the pump running smoothly for years.

2. Pump Design

The design of the pump is another important consideration. Pumps with fewer internal components are often easier to maintain. Ace Lobe Pumps has a design that simplifies maintenance tasks, with components that are easily accessible and replaceable, ensuring minimal disruption during servicing.

3. Seal Technology

Seals are an essential part of the pump's function. With Ace Lobe Pumps, the sealing systems are designed to last longer, reducing the need for frequent replacements. Choosing a pump with high-quality seals is a smart choice for businesses looking to reduce maintenance efforts.

The Role of Rotary Lobe Pumps in Various Industries

Rotary lobe pumps are used in many different industries due to their versatility and efficiency. Let's take a look at some of the industries where these pumps are most commonly employed:

1. Food and Beverage

In the food and beverage industry, sanitary conditions are paramount. Rotary lobe pumps are ideal for this sector because they can handle a variety of food products without damaging them. The easy maintenance features of Ace Lobe Pumps ensure that the pumps remain hygienic and efficient throughout their service life.

2. Pharmaceuticals

Pharmaceutical companies require pumps that can handle precise amounts of liquid without contaminating the product. Ace Lobe Pumps offer exceptional accuracy and cleanliness, making them perfect for pharmaceutical applications.

3. Chemical Processing

Chemical processing involves the handling of harsh and sometimes abrasive liquids. Rotary lobe pumps are designed to handle these challenging fluids without compromising performance. Their easy maintenance makes them an ideal choice for this sector, where downtime and contamination can lead to costly delays.

4. Wastewater Treatment

In wastewater treatment plants, rotary lobe pumps are used to transfer sludge and other viscous liquids. These pumps' easy-to-maintain design ensures that they can continue operating effectively in harsh conditions, reducing the need for constant repairs.

Conclusion

Rotary lobe pumps are an essential component in many industries, offering reliable and efficient fluid transfer. The design features that make these pumps easy to maintain—such as quick disassembly, durable sealing systems, and minimal wearing parts—help businesses reduce downtime, cut costs, and extend the lifespan of their equipment. Ace Lobe Pumps, with their user-friendly features and high-quality materials, offer businesses an excellent choice for reliable and cost-effective pumping solutions. Investing in a rotary lobe pump that is easy to maintain is a smart decision for any company looking to streamline their operations and reduce long-term maintenance costs.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Игры

- Gardening

- Health

- Главная

- Literature

- Music

- Networking

- Другое

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness