How Solid Fuel Steam Boilers Work: Principles and Benefits

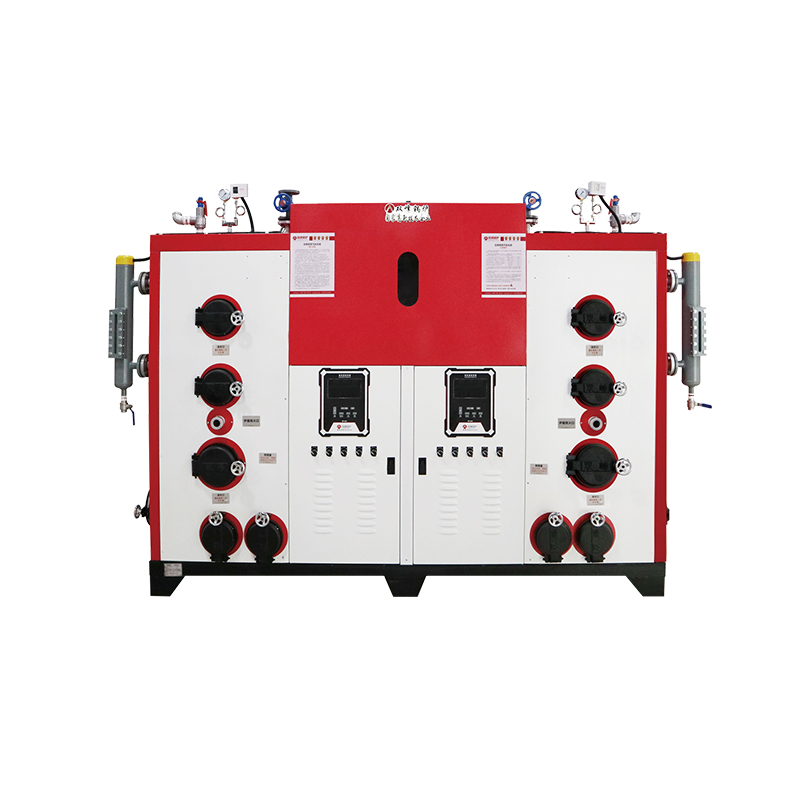

A solid fuel steam boiler is a vital piece of equipment in many industrial applications where high-pressure steam is needed for processes such as heating, power generation, and mechanical work. These boilers use solid fuels, such as coal, wood, or biomass, to generate heat, which is then used to produce steam. The solid fuel steam boiler has long been recognized for its efficiency and reliability in industries that require a consistent and robust supply of steam.

The primary advantage of a solid fuel steam boiler is its ability to use locally available fuels, which can reduce operating costs for businesses. Unlike natural gas or oil-fired boilers, solid fuel boilers do not rely on fluctuating fuel prices, making them an appealing choice in areas where solid fuels are abundant and affordable. This makes them especially useful in industries where fuel costs are a significant portion of operational expenses, such as in the paper, textile, and food processing industries.

Another benefit of solid fuel steam boilers is their environmental performance. When using biomass or other renewable solid fuels, these boilers can significantly reduce greenhouse gas emissions compared to traditional fossil fuel-based boilers. Biomass, for example, is considered carbon-neutral because the CO2 emitted during combustion is offset by the CO2 absorbed during the growth of the plants. This makes solid fuel boilers a more sustainable option for businesses looking to reduce their carbon footprint while still meeting their energy needs.

In terms of functionality, a solid fuel steam boiler is designed to provide a high level of thermal efficiency. Modern boilers use advanced combustion technology to ensure that the heat produced by burning solid fuels is maximized, reducing fuel consumption and enhancing overall boiler performance. The combustion process is closely monitored and controlled, allowing for optimal burn rates and minimal emissions. This not only helps reduce the environmental impact but also ensures that the boiler operates at peak efficiency, resulting in lower operating costs for the business.

Solid fuel steam boilers are highly versatile and can be tailored to meet the specific needs of different industries. They are designed to operate under varying pressure and temperature conditions, making them suitable for a wide range of applications, including steam turbines for power generation, industrial heating, and chemical processes. Additionally, solid fuel boilers can be used in combination with heat recovery systems, allowing for further optimization of energy usage.

Maintenance of solid fuel steam boilers is relatively straightforward, although regular servicing is required to ensure efficient and safe operation. The solid fuel combustion process can create ash and soot, which needs to be cleaned regularly to prevent build-up that could affect the performance of the boiler. Most modern boilers are equipped with automated cleaning systems to make this process easier and more efficient. Furthermore, the design of these boilers ensures that they have a long lifespan when properly maintained, making them a cost-effective investment for industrial applications.

In conclusion, a solid fuel steam boiler offers significant advantages in terms of cost-effectiveness, environmental performance, and versatility. By using locally available fuels, businesses can reduce fuel costs and minimize their dependence on external sources. The ability to operate efficiently, combined with a long service life and low maintenance requirements, makes solid fuel steam boilers an essential component of many industrial systems. As industries continue to seek more sustainable and cost-effective energy solutions, solid fuel steam boilers will likely remain a reliable and efficient choice.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Spellen

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Other

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness