How Much Do You Know About Offshore Oil Rigs

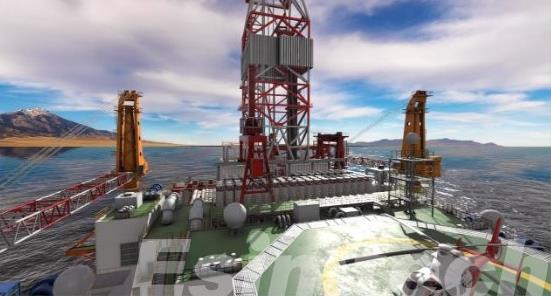

Offshore oil rigs stand as iconic symbols in the global energy sector, strategically positioned miles from shorelines, and have long been essential contributors to meeting the world’s energy needs. These colossal installations represent a fusion of engineering brilliance, innovative solutions, and a commitment to environmental responsibility.

This comprehensive article delves into the intricate world of offshore oil rigs, shedding light on their architectural and operational complexities, environmental implications, and their profound significance in the energy landscape. Additionally, we explore the crucial role of simulation technology in training personnel for the demanding operations conducted on these offshore installations.

The Evolution of Offshore Oil Rigs

The history of offshore oil exploration traces back to the early 20th century, driven by the depletion of onshore reserves and the quest for new hydrocarbon sources in oceanic realms. A significant milestone occurred in 1896 along the California coast with the emergence of the first offshore drilling platform, constructed from wood. This pioneering structure contrasts sharply with the sophisticated rigs dominating today's offshore landscapes.

Over time, offshore drilling has undergone remarkable evolution, propelled by cutting-edge technologies and a deeper understanding of the challenges posed by marine environments. The escalating demand for offshore drilling stems from the discovery of extensive, untapped oil and gas reservoirs beneath the ocean floor.

Operational Dynamics of Offshore Oil Rigs

Offshore oil rigs showcase human ingenuity and engineering prowess through intricate processes facilitating the extraction, processing, and transportation of hydrocarbons from deep seabeds to onshore facilities. Here's an overview of their operational mechanisms:

Exploration and Drilling: Seismic surveys identify potential reserves, followed by drilling of exploration wells to confirm hydrocarbon presence. Successful sites lead to drilling of production wells for resource extraction.

Production: Oil and gas are extracted through production wells, employing drilling rigs and wellheads on fixed platforms, or flexible risers/pipelines on floating systems.

Processing: Extracted fluids undergo separation and processing to remove impurities, separate oil and gas, and compress gas for transportation.

Storage: Oil is stored in tanks on FPSOs or floating platforms, awaiting offloading onto shuttle tankers. Gas may be reinjected, flared, or transported via pipelines.

Environmental Protection: Rig installations feature measures like oil spill containment, gas emission control, and adherence to safety protocols to mitigate environmental impact.

Types of Offshore Oil Rigs

Fixed Platforms: These structures, anchored to the seabed, include Jacket, Caisson, and Concrete Gravity platforms, suitable for various seabed conditions and depths.

Compliant Towers: Designed for deepwater drilling in challenging marine environments, these towers offer flexibility and structural integrity against high waves and currents.

Spar Platforms: Similar to compliant towers, spars excel in deepwater drilling, providing stability and safety in extreme conditions.

Tension-Leg Platforms (TLPs): Specialized for deepwater operations, TLPs ensure stability through tensioned tendons securing them to the seabed.

Floating Production, Storage, and Offloading (FPSO) Vessels: These floating facilities combine drilling, processing, storage, and offloading capabilities, crucial for deepwater extraction.

Drillships: Highly specialized vessels for deepwater drilling, equipped with advanced technology for mobility and exploration in remote offshore areas.

Semi-Submersibles: Buoyant rigs with water ballast tanks for stability, commonly used in deepwater and harsh sea conditions.

Simulation Technology in Offshore Operations

Simulation technology plays a pivotal role in training personnel for offshore rig operations:

Immersive Training: Simulators replicate real-world offshore environments, enabling trainees to tackle various challenges securely.

Skill Refinement: Trainees practice essential tasks like drilling and emergency responses until proficiency is attained.

Safety Training: Simulators facilitate comprehensive safety drills, ensuring personnel are prepared for critical situations.

Operational Efficiency:Simulated drilling scenarios enhance decision-making skills and response times, improving overall efficiency.

Cost Savings: Simulator-based training reduces expenses associated with conventional training methods, making it both cost-effective and resource-efficient.

Conclusion

Offshore oil rigs, remarkable feats of engineering, have played a significant role in global energy production. However, as we navigate towards a sustainable energy future, they face increased scrutiny for their environmental impact. Whether they continue as energy hubs or adapt to new roles, their importance in the energy industry remains undeniable.

Furthermore, the integration of simulation technology is vital for ensuring the safety and efficiency of offshore operations. By preparing the workforce for the complexities of offshore drilling, these simulations contribute to the ongoing success of offshore endeavors, underlining human innovation in the pursuit of energy resources.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Spiele

- Gardening

- Health

- Startseite

- Literature

- Music

- Networking

- Andere

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness