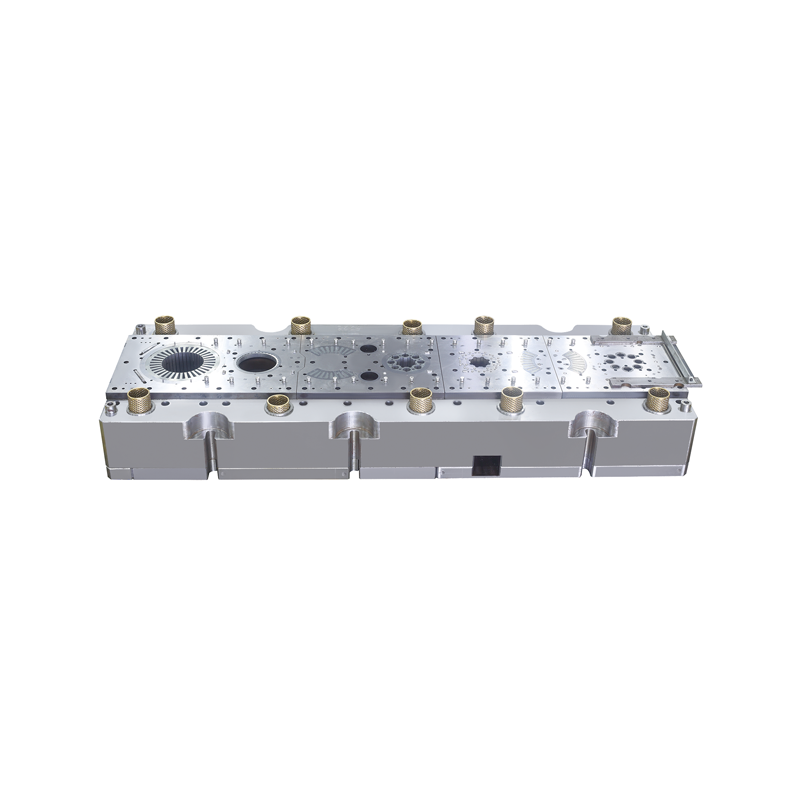

Progressive Stamping Mold: Multi-Stage Processing for Maximum Production Efficiency

Unlock the full potential of high-volume manufacturing with our Progressive Stamping Mold, expertly designed to perform multiple operations in one seamless process. Whether you are producing automotive components, electronic parts, or precision hardware, the Progressive Stamping Mold delivers unmatched speed, consistency, and efficiency.

The defining feature of the Progressive Stamping Mold is its ability to carry out several forming actions—such as punching, bending, drawing, and shaping—within a single mold and a continuous production cycle. As the metal strip advances through each station of the Progressive Stamping Mold, it undergoes a new forming process until the final product is completed at the end of the line. This integrated approach greatly reduces production time, making the Progressive Stamping Mold the ideal solution for mass production environments.

By eliminating the need for multiple machines and manual part transfers between processes, the Progressive Stamping Mold not only boosts productivity but also minimizes human error and improves overall product uniformity. Its compact and efficient design helps save valuable floor space while maximizing machine uptime.

The Progressive Stamping Mold is built for speed, precision, and long-term durability. Compatible with a wide range of metals and adaptable to different part geometries, this mold system is a versatile asset in any high-throughput production line.

For manufacturers seeking faster turnaround and lower operational costs, the Progressive Stamping Mold offers a streamlined path to success. Invest in the Progressive Stamping Mold today and experience the next level of stamping efficiency.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Jogos

- Gardening

- Health

- Início

- Literature

- Music

- Networking

- Outro

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness