Why Choose KENENG CNC Hardware Processing

Tools made from gold, silver, copper, iron, tin, and other metals for fixing, processing, and decorating are referred to as hardware. CNC machine tool processing refers to the use of a computer to construct a set of processing programs and the digital processing of things. CNC hardware processing comprises operations such as cutting, drilling, and tapping. CNC hardware processing can lower the rate of product wear and tear, which is highly valued by hardware and processing producers.

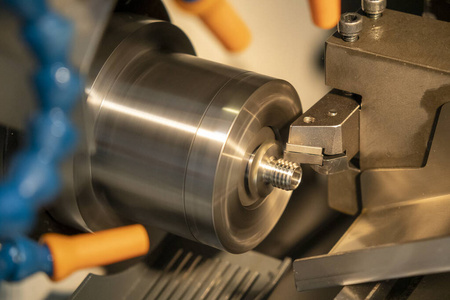

CNC machining is a type of machining and a new CNC hardware processing technology. The primary responsibility is to compile machining programs. Precision machining, CNC lathe processing, CNC milling machine processing, CNC boring and milling machine processing, and so on are all examples of general CNC processing. The CNC lathe feed processing route is the path that the turning tool takes from the tool setting point (or the machine tool's fixed origin) until it returns to this point and terminates the processing program. Cutting processing paths as well as non-cutting idle travel paths such as tool cut-in and cut-out are included.

The machining process of CNC machining tools is basically the same as that of ordinary machine tools in principle, but the whole process of CNC machining is carried out automatically.

The advantages of CNC hardware processing

1. There is a significant reduction in the number of tools. When cutting items with complex forms, complex tooling is not necessary. To change the shape and size of the part, just edit the part processing software, which is better suited for new product development and modification.

2. It can process complex profiles that would be difficult to process using traditional approaches, as well as certain unobservable processing elements. Because the program has control over it.

3. Production efficiency is higher when creating many types and small batches. The use of optimal stock removal reduces the time required for production preparation, machine adjustment, and process inspection, as well as cutting time.

4. High precision machining and consistent hardware quality. The dimensional precision of the machining is between 0.005-0.01 mm and is unaffected by the intricacy of the pieces. Because the machine performs the majority of the tasks, human error is eliminated, and the consistency of the batch size of components is enhanced. Furthermore, the precision control machine tool improves CNC cutting accuracy by incorporating a position sensing system.

5. High levels of automation. With the exception of human blank clamping, all other machining procedures can be accomplished automatically by CNC machine tools. CNC hardware processing minimizes the operator's work intensity, improves labor conditions, and effectively increases production efficiency.

6. It is simple to create computer communication and to implement group control. This is because the machine tool uses digital information control, making it simple to link to a computer-aided design system and construct a CAD/CAM integrated system.

About KENENG’s CNC hardware processing services

Types of CNC hardware processing materials that KENENG can provide

Stainless steel, copper (including brass, copper, beryllium copper, bronze, and other special copper), carbon steel (including various alloy steels), aluminum alloys, titanium alloys, and other special steels are examples of metal materials.

Types of CNC hardware processing products that KENENG can provide

Nylon, acrylic, PC, POM, PEEK, PF, and other insulation materials are available.

Compression springs, extension springs, torsion springs, die spring, wire spring, flat spiral spring, ferrite/ceramic magnet, smco magnet, permanent magnet, AlNiCo magnet, neodymium magnet.

KENENG has a long history of CNC hardware processing with high-precision metal casings.

Threading, tapping, milling, turning, drilling, wire EDM, custom finishing, prototype, low-volume part machining, modification of existing parts, and other services are available from KENENG.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Jogos

- Gardening

- Health

- Início

- Literature

- Music

- Networking

- Outro

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness