What Are Some Materials That Can Be Powder Coated?

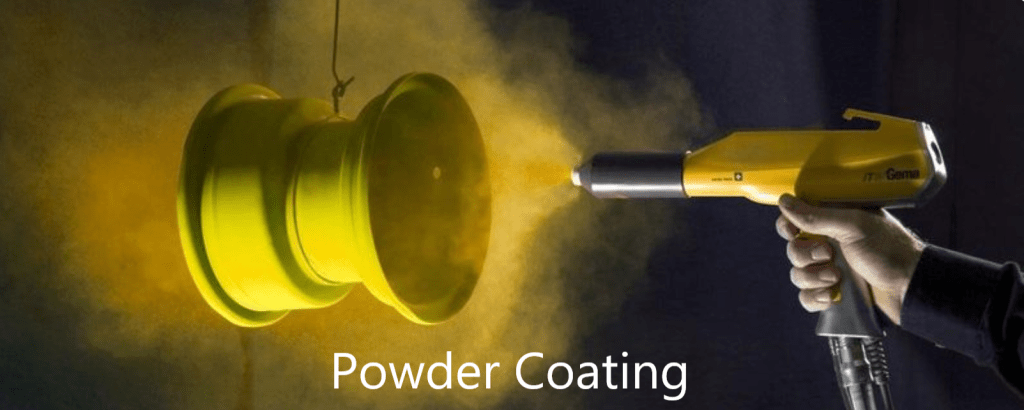

Powder coating is surprisingly versatile and can be applied to a variety of materials, with metal taking the top spot. Here's a breakdown of what can be powder coated:

Metals:

l Most common options: Aluminum, galvanized and electroplated steel, stainless steel, and various metal alloys. These materials react well to the curing process, forming a strong bond with the powder coat.

l Other possibilities: In some cases, cast iron, copper, and even titanium can be powder coated, but specialized techniques may be required.

Beyond Metal:

l Wood: Powder coating requires proper preparation and sealing to withstand the curing temperature. MDF and other engineered woods are popular choices.

l Glass: Produces a distinct and vibrant finish, but necessitates the use of special heat-resistant powders and careful handling.

l Plastics: Certain heat-resistant plastics can be powder coated, but compatibility testing is necessary.

l MDF and other composites: Powder coating is an option for a durable and attractive finish, but requires proper preparation and heat resistance.

Things to Consider:

l Material properties: Not all materials can withstand the high temperatures used in the curing process. Make sure the material is heat resistant and compatible with the powder coating you've chosen.

l Surface preparation: Preparation for powder coating varies by material and may include sanding, cleaning, and priming.

l Adhesion: Special adhesion promoters may be needed for certain materials to form a strong bond with the powder coating.

While metal continues to reign supreme in powder coating, technological and technique advancements are expanding the possibilities for coating other materials. With careful consideration and preparation, you can create stunning and long-lasting finishes on a variety of surfaces.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- الألعاب

- Gardening

- Health

- الرئيسية

- Literature

- Music

- Networking

- أخرى

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness