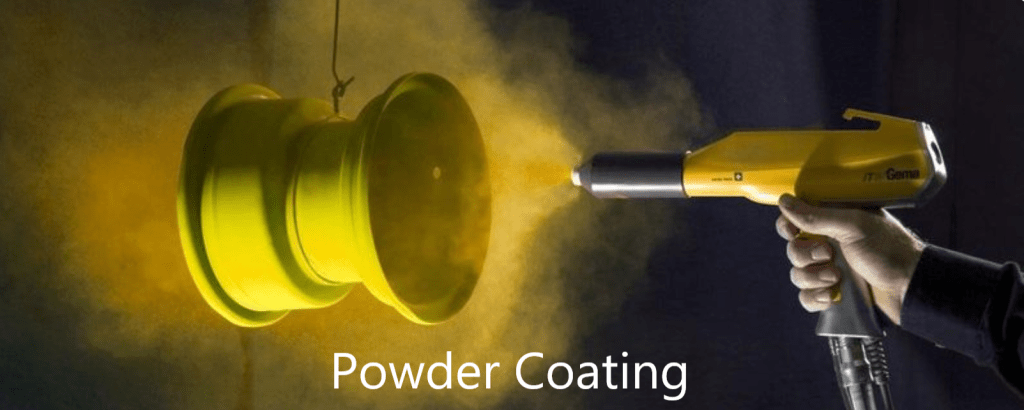

How Does Powder Coating Hold up to Scratches, Chips, and Fading?

Powder coatings are generally resistant to scratches, chips, and fading, making them a popular choice for applications requiring durability. Below is a breakdown of its performance in each area:

Scratches

l Highly resistant: Powder coating, due to its hardness and thickness, can withstand most minor scratches and abrasions. Light scratches might not even be visible.

l Depth matters: Deeper scratches that penetrate the coating can reveal the underlying material, but these are uncommon due to its resilience.

Chips

l Less prone: Powder coating, unlike paint, is less likely to chip due to its strong adhesion and tougher surface.

l Impact factors: Heavy impacts or sharp objects can cause chipping, particularly on edges and corners.

Fading

l UV-resistant: Powder coatings typically contain UV-resistant pigments that prevent fading from sunlight.

l Long-term exposure: UV-resistant coatings may fade over time, depending on the color and environment.

Here are some additional things to know:

l Type of powder coat: Powder coatings provide different levels of scratch, chip, and fade resistance. Consult with a professional to determine the best solution for your specific requirements.

l Surface preparation: Preparing the surface properly before applying powder coating improves adhesion and durability.

l Application quality: A skilled applicator will apply a thick, even coat, increasing scratch and chip resistance.

While no finish is indestructible, powder coating provides better protection against scratches, chips, and fading than most paints. Its superior durability makes it an excellent choice for a variety of applications, including outdoor furniture and bicycle frames, as well as kitchen appliances and industrial equipment.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Spellen

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Other

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness