The Artistry of Standard Nut Cold Heading Machines in Design

In the intricate world of design and manufacturing, where precision meets creativity, the Standard Nut Cold Heading Machine takes center stage as a silent maestro orchestrating the production of standard nuts. Let's embark on a journey to unravel the significance of this machine from a designer's perspective, exploring the nuances that make it an essential tool in the realm of industrial craftsmanship.

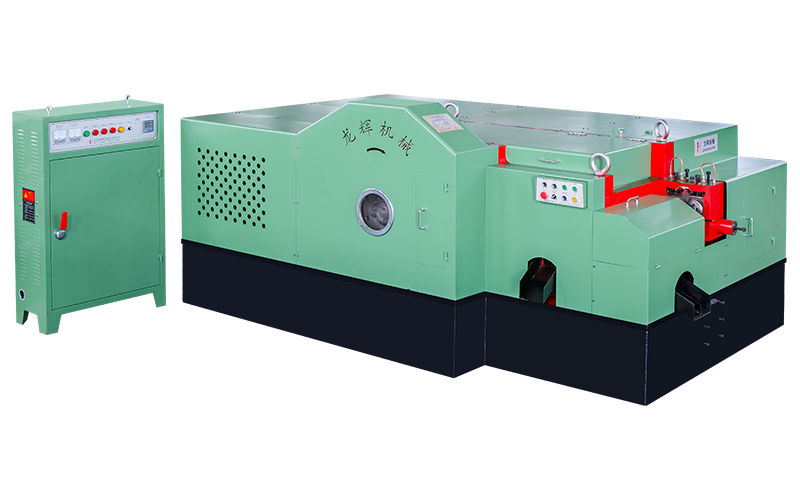

The Canvas of Industrial Design: Understanding Standard Nut Cold Heading Machines

At the heart of any assembly lies the nut—a seemingly simple yet indispensable component in the grand symphony of machinery and structures. The Standard Nut Cold Heading Machine emerges as a crucial artisan in this symphony, shaping and forming standard nuts with a blend of technological finesse and design intuition.

Precision in Motion: The Role of Standard Nut Cold Heading Machines in Design

Microscopic Artistry:

Standard Nut Cold Heading Machines empower designers with microscopic precision. The ability to finely shape and form nuts with exacting standards ensures the seamless integration of these components into various industrial designs.

Efficiency and Reliability:

These machines are crafted to optimize efficiency in nut production. Designers benefit from a reliable and streamlined process, allowing them to focus on the larger design narrative without concerns about the consistency of nut components.

Versatility in Design:

The Standard Nut Cold Heading Machine provides designers with a canvas of versatility. From different nut sizes to specific design requirements, the adaptability of these machines allows for the exploration of various design possibilities without compromising production efficiency.

Consistent Quality:

In the world of industrial design, consistency is paramount. Standard Nut Cold Heading Machines excel in maintaining uniformity across batches, ensuring that each nut meets the same high standards of quality and precision.

A Symphony of Features: The Anatomy of Standard Nut Cold Heading Machines

To truly appreciate the artistic potential of Standard Nut Cold Heading Machines, let's dissect the features that make them indispensable tools for designers:

Cold Heading Mechanism:

The heart of the operation lies in the cold heading mechanism. This feature ensures that nuts are formed without the need for excessive heat, preserving the integrity of the material and allowing for a more controlled and precise shaping process.

Tooling Systems for Design Flexibility:

Designers can exercise their creativity through advanced tooling systems. The machine allows for the creation of intricate nut designs, accommodating the diverse aesthetic and functional requirements of various industries.

Automated Precision:

Efficiency meets precision with automated systems that handle the cold heading process. Each nut undergoes a meticulously automated journey, minimizing errors and ensuring that the final product aligns with the designer's vision.

Digital Control Panel:

Designers are in command with the intuitive digital control panel. This interface allows for seamless interaction with the machine, providing control over every aspect of the nut production process.

Designing Tomorrow: Testimonials from Industrial Visionaries

Let's hear from industrial designers who have seamlessly integrated Standard Nut Cold Heading Machines into their creative processes:

Jonathan Rodriguez, Industrial Engineer:

"The precision offered by Standard Nut Cold Heading Machines has redefined how we approach the design of machinery. The consistency in nut quality is unparalleled, allowing us to build robust structures with confidence in the integrity of each component."

David Chen, Product Designer:

"As a product designer, the adaptability of these machines is a game-changer. I can experiment with different nut sizes and shapes effortlessly, knowing that the production process remains efficient and reliable. It's become an indispensable tool in my design studio."

The Future of Industrial Design: A Canvas of Possibilities

As the industrial design landscape continues to evolve, Standard Nut Cold Heading Machines stand as stalwart companions in the journey toward precision and efficiency. Designers can anticipate a future where the marriage of technology and design intuition reaches new heights, opening up endless possibilities in the realm of industrial craftsmanship.

In conclusion, the Standard Nut Cold Heading Machine emerges not just as a manufacturing tool but as a collaborator in the design narrative. It empowers designers to explore, create, and innovate without constraints, offering a canvas where artistry meets industrial precision. The intricate dance of form and function defines the narrative of Standard Nut Cold Heading Machines, making them indispensable allies for designers seeking to weave their design dreams into the fabric of industrial reality.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Jogos

- Gardening

- Health

- Início

- Literature

- Music

- Networking

- Outro

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness