What is squeeze casting why is it important how does it work what applications does it have and what are its advantages

挤压铸造技术的使用彻底改变了金属部件的生产,该技术是铸造和锻造制造工艺的新颖组合。

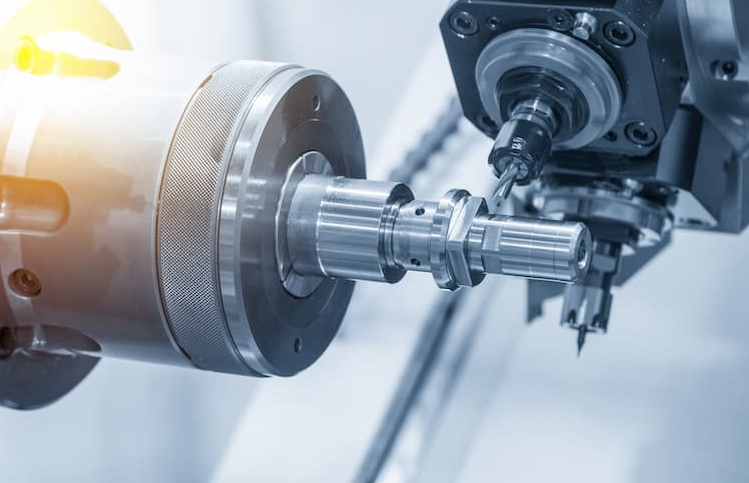

The procedure is important because it results in components that have remarkable strength while remaining nearly identical to the net shape that you specify. To achieve the best results, it is essential to have a solid understanding of how to control variables such as temperature, pressure, and the design of the die. Although there are some drawbacks to consider, squeeze-cast metal typically has fewer pores and better mechanical properties than other types. However, there are some drawbacks to consider. Squeeze casting will be defined, discussed, and analyzed in this article, along with its significance, method, applications, advantages, and disadvantages. Forging with liquid metal is another name for this process. In this method, molten metal is injected into a heated die, after which the molten metal is given time to start solidifying and the upper die is closed to create the mold chamber. Squeeze casting is utilized frequently in the production of auto parts.

What is the background of the process of squeeze casting? After that, in 1878, Chernov made some improvements to it. To reform molten metal, this cutting-edge process combined high temperatures with pressures of up to 15,000 pounds per square inch (psi). The purpose of the invention was to develop new approaches to metalworking, which would result in enhanced material properties and applications.

The manufacturing process known as squeeze casting is an important one. It allows for increased wettability of reinforcements, efficient mass production, precise control of process parameters, superior metallurgical quality through pressure-assisted solidification, and the ability to selectively reinforce specific regions within components. Because of these characteristics, it is an excellent option for the production of metal matrix composites of high quality.

The process of squeeze casting involves pouring molten metal into a heated die, where it is combined with a preform that was made using powder metallurgy. After all of the metal has been loaded into the die, pressure is applied, and then the metal is left to harden.

Squeeze casting is distinct from other casting methods because of its one-of-a-kind combination of high-pressure component production and near-net-shaped component formation during the solidification process.

-

Die casting is not the same thing as squeeze casting, and vice versa

-

Die-casting machines inject molten metal into a mold cavity, whereas squeeze-casting metal requires additional pressure to be applied to the molten metal

-

As a consequence, the mechanical properties are improved, and the number of defects is reduced

-

After that, it is moved slowly (typically at a speed of less than 0

-

5 meters per second) into the cavity of the aluminum die-casting part by pushing it through relatively large gates

2. 在金属刚开始凝固后不久就施加压力,甚至在铸件完全凝固后仍继续施加压力。

锌挤压铸造技术用于锌基合金,其特点是熔点相对较低。由于其卓越的流动性,锌是复杂零件几何形状的绝佳选择。

镁,第二号

3. 在凝固阶段,液态铝合金被引入 已预热的 铝压铸部件中,然后在压力下成型。铝压铸件 因其优异的强度、耐腐蚀性和多功能性而成为各种应用中非常受欢迎的选择。

4. 铜和铜合金铜合金

挤压铸造包括生产黄铜和青铜等材料,这些材料因其卓越的耐用性和导电性而备受推崇。然而,这些产品的高成本及其所拥有的特殊材料特性使其难以在市场上竞争。

在挤压铸造过程中,是否可以使用不锈钢作为铸造金属之一?

请参阅我们的不锈钢金属指南了解更多信息。

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Giochi

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Altre informazioni

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness