Comparison of Features Costs and Advantages and Disadvantages of CNC Drafting Software as a Means of Making an Informed Purchasing Decision

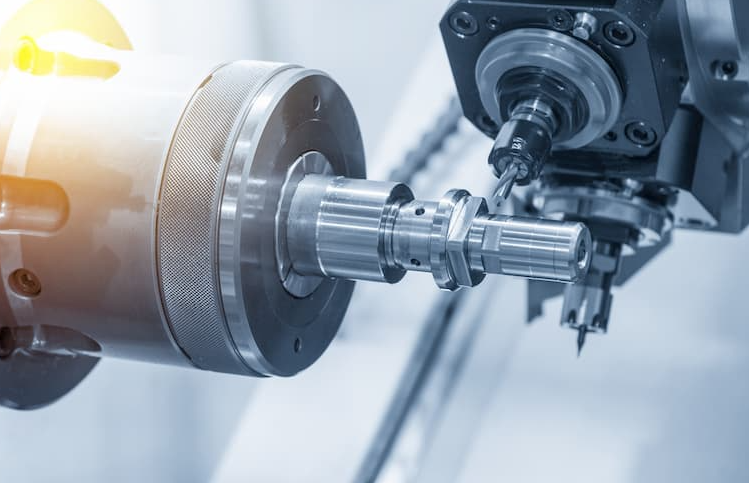

In this day and age of digital manufacturing, having the appropriate CNC drafting software has developed into an essential component of mechanical machining. Consequently, the mechanical machining process must be performed. Utilizing CNC drafting software that is not only all-encompassing in terms of the capabilities it possesses but also inexpensive in terms of its price is one of the most effective ways to significantly boost the efficiency of mechanical design and production. This article will provide professionals in the manufacturing industry with specific recommendations on how to choose CNC drafting software. Additionally, a comparison of the benefits and drawbacks of using commercial software versus open-source software will be provided. A Popular and Powerful Piece of Software for CNC DraftingThe utilization of CNC drafting software is obligatory for both the generation of process files and the programming of CNC machine tools. CNC drafting software typically takes the form of powerful 3D CAD/CAM/CAE programs like the one known as UG, which is just one example of this type of software. UG was initially developed by UG Corporation, which is based in the United States. It combines intuitive direct modeling with parametric feature-based characteristics, and it can be used for both the design of complex 3D parts and the programming of NC machines.

In addition, it combines these two types of modeling approaches in a single application

1. UG combines many different functions, such as drawing in two dimensions, modeling in three dimensions, defining assembly relationships, and powerful capabilities for surface modeling

2. Gains to Obtain: Extremely functional, with the capacity to design as well as simulate complex engineering components and assemblies

3. In addition to that, it can perform sophisticated simulations of 5-axis machining and it is compatible with a wide range of programming strategies

4. a significant amount of parametric modeling as well as the capability to make adaptable changes to the design

5. possesses the tools necessary for accurately modeling various constructional features

6. Modifiable in the sense that it can be altered to fulfill a wide variety of needs and wants

7. In addition to providing services for technical support, this company also provides extensive training resources

8. The cost of the software is high, and there are significant additional expenses involved in mastering it and putting it to use

9. The user interface was difficult to navigate, and the software was notoriously difficult to operate

10. Additionally, the software had a steep learning curve

requiring computer systems with a high configuration to operate correctly. A high level of resource occupancy may be the result of an excessive number of functions being performed. Mastercam is a piece of CAD/CAM software that was developed by CNC Software, which is based in the United States. It is widely considered to be among the most popular pieces of CAD/CAM software that can be found anywhere in the world. It can support a wide variety of machining processes thanks to its powerful 3D design capabilities and efficient NC code programming. Some of these processes include turning, milling, wire cutting, and wire machining. In addition, the simulation and verification functions that are included in Mastercam can be utilized to locate errors that may be present in NC programs. Dassault Systèmes, a French company, is the creator of the 3D mechanical CAD software known as SolidWorks. Dassault Systèmes is based in France. By utilizing parametric feature modeling, Mold Making can achieve a greater degree of design flexibility. SolidWorks provides users with access to an integrated CAM module that can be used for NC programming. Its capabilities include automatic G code generation as well as simulation, both of which allow it to generate machining programs in a manner that is accurate as well as time-efficient.

Delcam, based in the United Kingdom, is responsible for the creation of the powerful 3D NC programming software known as PowerMill. It can perform complex machining on three to five axes because it is outfitted with sophisticated algorithms for the generation of tool paths that are high-speed as well as highly efficient. This makes it possible for it to handle multiple simultaneous operations. The number of different machine tool brands that are compatible with PowerMill is quite extensive. Which Types of Files Are Capable of Being Imported and Exported Utilizing These Programs? The vast majority of common file formats used by CAD and CAM programs can be imported and exported by software used for CNC drafting. The following are some of these file formats, but the list is not exhaustive:• Importing Different Types of Files: IGES is a file format that has become the industry standard for 3D computer-aided design models, and the vast majority of CNC software programs can read and write in this format. Both the geometric and topological information of models can be preserved using STEP, which is an international standard for the file formats used by 3D solid CAD mold-making programs.

STL is a file format that describes the surfaces of 3D models and is used in the process of stereolithography, which is a type of 3D printing. The AutoCAD file format known as DXF is used for two-dimensional drawings and stores graphics vector information. AutoCAD's 2D and 3D design graphics must be saved in the DWG format for it to work properly.• Exporting Files in the Following Formats: The terms "G-code" and "M-code" refer to control codes that are directly readable by CNC machine tools. The CL data stores machine tool-specific machining program codes for use in the machining process. It is possible to export DXF files so that they can be used in AutoCAD or one of the many other 2D design programs. The STL file format, which is used for meshes, can be utilized to facilitate the process of rapid prototyping. PDF is a format that is simple to work with, and it can be used to store two-dimensional engineering drawings alongside annotations. IGES and STEP are two examples of neutral file formats that can preserve information about 3D models.

Where to Look for the Best CNC Drafting Software: What to Look For? The Steep Hill of EducationThe learning curve for paid CNC software like UG and Mastercam is significantly steeper than that of free alternatives. Despite their power, commercial CNC software is expensive. There is software that is available for free that is user-friendly for novices, and some examples of this software are FreeCAD and Fusion 360. Hardware Requirements, in Terms of PrerequisitesWhen running commercial CNC software, a processor with a high-performance level and a significant amount of memory are both necessities. For example, Mastercam recommends having a minimum of 16 gigabytes of random access memory (RAM). Some free software has less stringent hardware requirements than others, and it runs smoothly regardless of those requirements. Being Able to Program Commercial software typically provides support for more complex forms of machine tool programming, such as multi-axis and rotary machining. The machining on three axes is the primary focus of the programming for free software, which is typically quite user-friendly. Service and Maintenance Following a PurchaseCommercial software typically comes with comprehensive and up-to-date support and update services that can be accessed at any time. The user community is responsible for the maintenance and updating of any software that is freely distributed and offered under an open-source license.

Various alterations made to Customer SpecificationsThe use of commercial software makes it feasible to customize and adapt responses to meet the unique requirements of individual customers. When it comes to the individual functions of the software, there is less room for customization when using open-source software. Trade of InformationCommercial software typically provides extensive support for importing and exporting data in a variety of computer-aided design (CAD) and computer-aided manufacturing (CAM) file formats. The open-source software only provides support for a select few different file formats.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Jogos

- Gardening

- Health

- Início

- Literature

- Music

- Networking

- Outro

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness