Super-Resolution Microscopes in Nanotechnology, Materials Science, and Semiconductor Applications

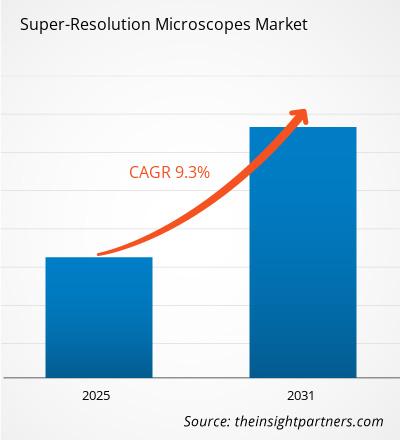

While life sciences dominate adoption, the Super-Resolution Microscopes Market is increasingly gaining traction in nanotechnology, material science, and semiconductor industries. These sectors require precise visualization and characterization of structures at the nanoscale, making super-resolution microscopy a critical analytical tool. This expanding industrial adoption significantly contributes to the market’s projected growth to US$ 8.5 billion by 2031, at a 9.2% CAGR.

Nanotechnology: Precision at the Nanoscale

Nanotechnology research focuses on materials and structures typically ranging from 1 to 100 nanometers. Super-resolution microscopy enables researchers to:

Visualize nanoparticles and nanostructures

Study nano-bio interfaces

Analyze surface functionalization

Techniques such as STORM and PALM are particularly effective in nanotechnology due to their single-molecule localization capabilities.

Companies like Bruker and JEOL Ltd provide advanced platforms that combine optical precision with analytical stability, making them suitable for cutting-edge nanotechnology research.

Material Science Applications

Material science relies on understanding structure-property relationships at the microscopic and nanoscopic levels. Super-resolution microscopes allow scientists to investigate:

Polymer morphology

Composite material interfaces

Thin-film structures

Surface defects and stress points

By revealing nanoscale defects and structural variations, these systems help researchers optimize material performance and durability.

Hitachi High-Technologies Corporation and Danaher are key contributors to this segment, offering systems tailored for industrial R&D and advanced materials characterization.

Semiconductor Industry and Advanced Electronics

The semiconductor industry is one of the fastest-growing application areas for super-resolution microscopy. As transistor sizes shrink and device architectures become more complex, traditional inspection tools are no longer sufficient.

Super-resolution microscopy supports:

Failure analysis

Defect detection

Process optimization

Research into next-generation semiconductor materials

Hybrid imaging approaches that integrate optical microscopy with computational enhancement are increasingly adopted to meet the industry’s evolving needs.

Role in Quality Control and Industrial R&D

Industrial laboratories use super-resolution microscopes for quality control, product development, and failure analysis. These applications require high throughput, repeatability, and integration with existing analytical workflows.

Manufacturers respond by offering:

Automated imaging systems

Advanced software analytics

Modular system designs

This trend enhances usability and broadens adoption beyond specialized research facilities.

Cross-Industry Collaboration and Innovation

The convergence of nanotechnology, material science, and electronics is driving interdisciplinary research. Super-resolution microscopy plays a key role in this convergence by providing a common analytical platform across disciplines.

Collaborations between instrument manufacturers and industrial R&D centers are accelerating innovation and expanding market opportunities.

Future Outlook for Industrial Applications

As industries continue to push technological boundaries, demand for advanced imaging solutions will grow. Super-resolution microscopes will increasingly be integrated with other analytical techniques, such as spectroscopy and electron microscopy, to provide comprehensive material insights.

In conclusion, non-biological applications are becoming an essential growth pillar for the Super-Resolution Microscopes Market, complementing life sciences and reinforcing the market’s strong outlook through 2031.

https://www.theinsightpartners.com/reports/super-resolution-microscopes-marketSuper-Resolution Microscopes in Nanotechnology, Materials Science, and Semiconductor Applications

While life sciences dominate adoption, the Super-Resolution Microscopes Market is increasingly gaining traction in nanotechnology, material science, and semiconductor industries. These sectors require precise visualization and characterization of structures at the nanoscale, making super-resolution microscopy a critical analytical tool. This expanding industrial adoption significantly contributes to the market’s projected growth to US$ 8.5 billion by 2031, at a 9.2% CAGR.

Nanotechnology: Precision at the Nanoscale

Nanotechnology research focuses on materials and structures typically ranging from 1 to 100 nanometers. Super-resolution microscopy enables researchers to:

Visualize nanoparticles and nanostructures

Study nano-bio interfaces

Analyze surface functionalization

Techniques such as STORM and PALM are particularly effective in nanotechnology due to their single-molecule localization capabilities.

Companies like Bruker and JEOL Ltd provide advanced platforms that combine optical precision with analytical stability, making them suitable for cutting-edge nanotechnology research.

Material Science Applications

Material science relies on understanding structure-property relationships at the microscopic and nanoscopic levels. Super-resolution microscopes allow scientists to investigate:

Polymer morphology

Composite material interfaces

Thin-film structures

Surface defects and stress points

By revealing nanoscale defects and structural variations, these systems help researchers optimize material performance and durability.

Hitachi High-Technologies Corporation and Danaher are key contributors to this segment, offering systems tailored for industrial R&D and advanced materials characterization.

Semiconductor Industry and Advanced Electronics

The semiconductor industry is one of the fastest-growing application areas for super-resolution microscopy. As transistor sizes shrink and device architectures become more complex, traditional inspection tools are no longer sufficient.

Super-resolution microscopy supports:

Failure analysis

Defect detection

Process optimization

Research into next-generation semiconductor materials

Hybrid imaging approaches that integrate optical microscopy with computational enhancement are increasingly adopted to meet the industry’s evolving needs.

Role in Quality Control and Industrial R&D

Industrial laboratories use super-resolution microscopes for quality control, product development, and failure analysis. These applications require high throughput, repeatability, and integration with existing analytical workflows.

Manufacturers respond by offering:

Automated imaging systems

Advanced software analytics

Modular system designs

This trend enhances usability and broadens adoption beyond specialized research facilities.

Cross-Industry Collaboration and Innovation

The convergence of nanotechnology, material science, and electronics is driving interdisciplinary research. Super-resolution microscopy plays a key role in this convergence by providing a common analytical platform across disciplines.

Collaborations between instrument manufacturers and industrial R&D centers are accelerating innovation and expanding market opportunities.

Future Outlook for Industrial Applications

As industries continue to push technological boundaries, demand for advanced imaging solutions will grow. Super-resolution microscopes will increasingly be integrated with other analytical techniques, such as spectroscopy and electron microscopy, to provide comprehensive material insights.

In conclusion, non-biological applications are becoming an essential growth pillar for the Super-Resolution Microscopes Market, complementing life sciences and reinforcing the market’s strong outlook through 2031.

https://www.theinsightpartners.com/reports/super-resolution-microscopes-market