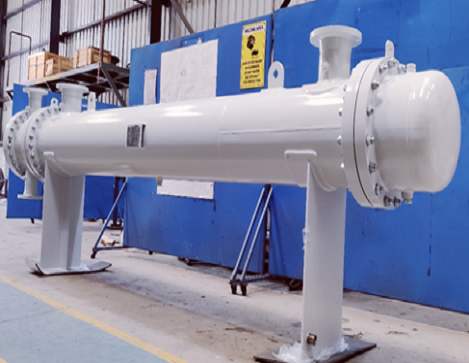

Enhancing Efficiency with Non-Ferrous Heat Exchangers – A Smart Choice by Gas Processing

In industries where corrosion resistance, thermal efficiency, and longevity are critical, Non-Ferrous Heat Exchangers have become the preferred solution. Whether it's chemical processing, power generation, or HVAC systems, choosing the right heat exchanger material can make a massive difference in performance and maintenance costs.

At Gas Processing, we specialize in advanced, custom-engineered non-ferrous heat exchangers that offer superior performance and reliability across a wide range of industrial applications.

What Are Non-Ferrous Heat Exchangers?

Non-ferrous heat exchangers are built using metals that do not contain significant amounts of iron. Common non-ferrous materials include:

Copper

Aluminum

Brass

Titanium

Nickel Alloys

These materials are chosen for their excellent corrosion resistance, lightweight properties, and superior thermal conductivity compared to ferrous metals like steel.

Key Benefits of Non-Ferrous Heat Exchangers

1. Corrosion Resistance

In industries dealing with aggressive fluids, saltwater, or acidic environments, corrosion is a major challenge. Non-ferrous metals like copper-nickel and titanium resist corrosion far better than carbon steel, significantly extending the life of the heat exchanger.

2. Superior Thermal Conductivity

Materials like copper and aluminum are excellent conductors of heat, allowing faster and more efficient heat transfer. This leads to better energy efficiency and smaller unit sizes.

3. Lightweight and Compact

Non-ferrous heat exchangers are often lighter, making them easier to install and maintain. Their compact design also allows for greater space savings in tight installations.

4. Low Maintenance Requirements

Because of their resistance to scale, corrosion, and fouling, non-ferrous exchangers require less frequent cleaning and inspection—reducing operational downtime.

Applications of Non-Ferrous Heat Exchangers

Non-ferrous heat exchangers are used in various industries, including:

Chemical & Petrochemical Plants

Marine and Offshore Applications

Power Generation

Pharmaceuticals

Food & Beverage Processing

HVAC & Refrigeration Systems

Their versatility and robustness make them suitable for both high-pressure and high-temperature environments.

Why Choose Gas Processing?

At Gas Processing, we combine decades of engineering expertise with state-of-the-art manufacturing technology to deliver non-ferrous heat exchangers that are:

Custom-designed to meet your specific process needs

Manufactured to international standards (ASME, TEMA, ISO)

Available in various configurations: shell & tube, plate, finned, and more

Rigorously tested for quality, pressure, and performance

Our team works closely with clients from concept to commissioning, ensuring a seamless integration into your process system.

Conclusion

Whether you're upgrading an existing system or designing a new plant, choosing a non-ferrous heat exchanger can dramatically improve your system's durability, efficiency, and reliability. With Gas Processing, you're not just buying a product—you're investing in performance, precision, and peace of mind.

Ready to elevate your heat transfer solutions? Contact Gas Processing today to discuss your non-ferrous heat exchanger requirements.

Visit us

https://gasprocessing.in/processing-equipment/

Non-Ferrous Heat exchanger, Heat Exchanger Manufacturer in India

Enhancing Efficiency with Non-Ferrous Heat Exchangers – A Smart Choice by Gas Processing

In industries where corrosion resistance, thermal efficiency, and longevity are critical, Non-Ferrous Heat Exchangers have become the preferred solution. Whether it's chemical processing, power generation, or HVAC systems, choosing the right heat exchanger material can make a massive difference in performance and maintenance costs.

At Gas Processing, we specialize in advanced, custom-engineered non-ferrous heat exchangers that offer superior performance and reliability across a wide range of industrial applications.

What Are Non-Ferrous Heat Exchangers?

Non-ferrous heat exchangers are built using metals that do not contain significant amounts of iron. Common non-ferrous materials include:

Copper

Aluminum

Brass

Titanium

Nickel Alloys

These materials are chosen for their excellent corrosion resistance, lightweight properties, and superior thermal conductivity compared to ferrous metals like steel.

Key Benefits of Non-Ferrous Heat Exchangers

1. Corrosion Resistance

In industries dealing with aggressive fluids, saltwater, or acidic environments, corrosion is a major challenge. Non-ferrous metals like copper-nickel and titanium resist corrosion far better than carbon steel, significantly extending the life of the heat exchanger.

2. Superior Thermal Conductivity

Materials like copper and aluminum are excellent conductors of heat, allowing faster and more efficient heat transfer. This leads to better energy efficiency and smaller unit sizes.

3. Lightweight and Compact

Non-ferrous heat exchangers are often lighter, making them easier to install and maintain. Their compact design also allows for greater space savings in tight installations.

4. Low Maintenance Requirements

Because of their resistance to scale, corrosion, and fouling, non-ferrous exchangers require less frequent cleaning and inspection—reducing operational downtime.

Applications of Non-Ferrous Heat Exchangers

Non-ferrous heat exchangers are used in various industries, including:

Chemical & Petrochemical Plants

Marine and Offshore Applications

Power Generation

Pharmaceuticals

Food & Beverage Processing

HVAC & Refrigeration Systems

Their versatility and robustness make them suitable for both high-pressure and high-temperature environments.

Why Choose Gas Processing?

At Gas Processing, we combine decades of engineering expertise with state-of-the-art manufacturing technology to deliver non-ferrous heat exchangers that are:

Custom-designed to meet your specific process needs

Manufactured to international standards (ASME, TEMA, ISO)

Available in various configurations: shell & tube, plate, finned, and more

Rigorously tested for quality, pressure, and performance

Our team works closely with clients from concept to commissioning, ensuring a seamless integration into your process system.

Conclusion

Whether you're upgrading an existing system or designing a new plant, choosing a non-ferrous heat exchanger can dramatically improve your system's durability, efficiency, and reliability. With Gas Processing, you're not just buying a product—you're investing in performance, precision, and peace of mind.

📞 Ready to elevate your heat transfer solutions? Contact Gas Processing today to discuss your non-ferrous heat exchanger requirements.

Visit us https://gasprocessing.in/processing-equipment/

Non-Ferrous Heat exchanger, Heat Exchanger Manufacturer in India