Who is SSM?

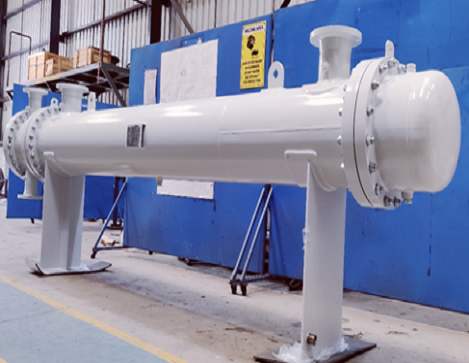

SSM is a professional and leading manufacturer, distributor, stockist of flanges, forgings, etc. in China for a wild range of industries like Renewable Energy, Wind-Mill Plant, Oil & Gas Industries, Onshore, Offshore, Refinery, Petrochemicals, Water & WWTP, Food Processing Inds, Power & Shipbuilding Industries, Automotive, Heat Exchanger, Pressure Vessel, Paper Mills, Valve, Mining, etc.

With more than 30 years of experience in flange developing, manufacturing, and marketing, SSM is dedicated to meeting all of your pipe flange needs including any customized jobs. SSM is proud to provide fast, reliable service at price that you can afford.

What Type of Flanges SSM Supply?

SSM supplies steel pipe flanges including Plate Flange, Blind Flange, Orifice Flange, Lap Joint Flange, Slip-On Flange, Socket Weld Flange, Threaded Flange, Weld Neck Flange, Spectacle Blind, Paddle Blinds, Spacer Rings and more to meet all specifications including ASME B16.5 ASME B16.47 ASME B16.48 ASME B16.36 AWWA C207, DIN, JIS, EN1902-1, Norsok, BS, AS standards, etc. SSM also supplies customized forgings, rings, shafts, discs, bleed rings, etc. as per the drawing.

What Material SSM Supply?

SSM manufactures flanges in all material grades, including Hastelloy C276 C22 B2 B3 C2000 X, Inconel600 601 625, Incoloy800 800H 800HT 826 926, Monel400, Alloy 20, Alloy 31, duplex stainless steel S32205 S31803 S32750 904L 254SMO, stainless steel 304 304L 304H 316 316L 316H 316Ti 317 317L 347 347H 310 310H, Alloy steel A182 F5 F9 F11 F12 F22 F91, Carbon steel A694 F42 F52 F65 F70 A105N A350 LF2 LF3, Titanium Gr.2, etc.

Why SSM?

1. Solve Your Special Metals Needs

Our extensive knowledge of materials and melting mills source allows us to locate hard to find materials and products to meet your machining and delivery requirements.

2. Save You Not Only Money But Time As Well

Take advantage of SSM sales team's knowledge of our mill' s capabilities and current inventories.

SSM can meet your specific needs from a wide array of sources to get you the best price and delivery possible.

What might take you weeks we can often obtain within a day or two.

3. Use SSM'S Volume to Leverage Your Purchases

Our cooperation with different steel mills allows us to obtain the most competitive pricing available.

4. Best Quality Control

Our elite sales staff and our veteran machinists work together to ensure that the highest quality of care is implemented in every stage of creating each precision engineered flange that leaves our shop. Our QC department works tirelessly to inspect each flange before releasing it for shipping.

5. One Stop-Solution In Steel Products

Custom forgings and flanges are our specialties, but we can also supply bar, plate, and many other metal components that you might need for your particular job.

In lieu of multiple purchase orders, you can accomplish all your needs with a single purchase order to SSM.

We can arrange to ship your entire order to save you transportation costs, or we can do partial shipments as you need the material.

6. On-Time Delivery

We understand the importance of on-time deliveries and do all production schedules strictly.

7. Multiple solutions

SSM can quote your materials; rough turned, semi-finished, or finished machined, and can provide destructive or non-destructive testing as required. Our competitive machining rates can allow you to maximize your internal capabilities for other areas.ASME SB564 Nickel 200 Blind BL Flange

website:

http://www.sinospecialmetals.com/Who is SSM?

SSM is a professional and leading manufacturer, distributor, stockist of flanges, forgings, etc. in China for a wild range of industries like Renewable Energy, Wind-Mill Plant, Oil & Gas Industries, Onshore, Offshore, Refinery, Petrochemicals, Water & WWTP, Food Processing Inds, Power & Shipbuilding Industries, Automotive, Heat Exchanger, Pressure Vessel, Paper Mills, Valve, Mining, etc.

With more than 30 years of experience in flange developing, manufacturing, and marketing, SSM is dedicated to meeting all of your pipe flange needs including any customized jobs. SSM is proud to provide fast, reliable service at price that you can afford.

What Type of Flanges SSM Supply?

SSM supplies steel pipe flanges including Plate Flange, Blind Flange, Orifice Flange, Lap Joint Flange, Slip-On Flange, Socket Weld Flange, Threaded Flange, Weld Neck Flange, Spectacle Blind, Paddle Blinds, Spacer Rings and more to meet all specifications including ASME B16.5 ASME B16.47 ASME B16.48 ASME B16.36 AWWA C207, DIN, JIS, EN1902-1, Norsok, BS, AS standards, etc. SSM also supplies customized forgings, rings, shafts, discs, bleed rings, etc. as per the drawing.

What Material SSM Supply?

SSM manufactures flanges in all material grades, including Hastelloy C276 C22 B2 B3 C2000 X, Inconel600 601 625, Incoloy800 800H 800HT 826 926, Monel400, Alloy 20, Alloy 31, duplex stainless steel S32205 S31803 S32750 904L 254SMO, stainless steel 304 304L 304H 316 316L 316H 316Ti 317 317L 347 347H 310 310H, Alloy steel A182 F5 F9 F11 F12 F22 F91, Carbon steel A694 F42 F52 F65 F70 A105N A350 LF2 LF3, Titanium Gr.2, etc.

Why SSM?

1. Solve Your Special Metals Needs

Our extensive knowledge of materials and melting mills source allows us to locate hard to find materials and products to meet your machining and delivery requirements.

2. Save You Not Only Money But Time As Well

Take advantage of SSM sales team's knowledge of our mill' s capabilities and current inventories.

SSM can meet your specific needs from a wide array of sources to get you the best price and delivery possible.

What might take you weeks we can often obtain within a day or two.

3. Use SSM'S Volume to Leverage Your Purchases

Our cooperation with different steel mills allows us to obtain the most competitive pricing available.

4. Best Quality Control

Our elite sales staff and our veteran machinists work together to ensure that the highest quality of care is implemented in every stage of creating each precision engineered flange that leaves our shop. Our QC department works tirelessly to inspect each flange before releasing it for shipping.

5. One Stop-Solution In Steel Products

Custom forgings and flanges are our specialties, but we can also supply bar, plate, and many other metal components that you might need for your particular job.

In lieu of multiple purchase orders, you can accomplish all your needs with a single purchase order to SSM.

We can arrange to ship your entire order to save you transportation costs, or we can do partial shipments as you need the material.

6. On-Time Delivery

We understand the importance of on-time deliveries and do all production schedules strictly.

7. Multiple solutions

SSM can quote your materials; rough turned, semi-finished, or finished machined, and can provide destructive or non-destructive testing as required. Our competitive machining rates can allow you to maximize your internal capabilities for other areas.ASME SB564 Nickel 200 Blind BL Flange

website:http://www.sinospecialmetals.com/