-

2 Articoli

-

0 Foto

-

0 Video

-

Male

-

12/11/2000

-

Seguito da 0 persone

© 2026 Scenario.press - libera espressione

Italiano

Italiano

Aggiornamenti recenti

-

Precision in Every Curve: How CNC Bending is Revolutionizing Metal Fabrication

In the ever-evolving world of metal fabrication, precision and efficiency are no longer optional—they’re essential. Modern manufacturing demands tight tolerances, consistent results, and faster turnaround times. This is where CNC Bending Services have emerged as a game-changer, redefining how industries approach metal shaping and forming.

What Is CNC Bending?

CNC (Computer Numerical Control) Bending is a process that uses computer-controlled machines to bend sheet metal with extreme precision. Unlike manual bending, CNC technology allows for repeatable, error-free production, ensuring each part matches exact specifications. This technology is commonly used for materials like steel, aluminum, and stainless steel, producing components for automotive, construction, aerospace, and industrial applications.

The Power of Precision in Metal CNC Bending

Every angle, curve, and fold in a metal part affects the product’s overall quality and performance. Metal CNC Bending ensures unmatched accuracy by using advanced software to control the bending angles, pressure, and sequence. This reduces human error and material waste while maintaining consistent quality throughout production.

For manufacturers, this precision translates to better fitting parts, reduced rework, and improved product durability—all while saving time and costs.

Key Advantages of CNC Bending Services

High Accuracy and Consistency

CNC bending machines follow pre-programmed commands to deliver consistent results, no matter how complex the design.

Efficiency and Speed

Automated setups and quick tooling adjustments make CNC bending ideal for both small and large-volume production.

Design Flexibility

From simple angles to intricate shapes, CNC bending can handle diverse designs, allowing engineers more creative freedom.

Cost-Effective Production

With reduced labor requirements and minimal waste, CNC bending is one of the most economical methods for precision metal fabrication.

Enhanced Durability

The precise bending process ensures uniform stress distribution across the metal, improving the strength and longevity of components.

Applications of Metal CNC Bending

CNC bending plays a crucial role in producing components such as brackets, enclosures, frames, and panels used across various industries. Whether it’s the automotive sector needing structural parts or the construction industry requiring custom-fit panels, CNC bending provides the adaptability and precision modern projects demand.

Why Choose Raamps Industries for CNC Bending Services?

Raamps Industries stands at the forefront of CNC Bending Services, combining advanced technology with years of industry expertise. The company delivers tailored Metal CNC Bending solutions that meet strict client specifications while maintaining exceptional quality and turnaround speed. From prototype development to full-scale production, Raamps Industries ensures every curve, edge, and angle meets perfection.

Conclusion

The future of metal fabrication lies in precision, speed, and efficiency—and CNC Bending Services perfectly embody these principles. As industries continue to innovate and demand higher standards, Metal CNC Bending will remain a cornerstone of modern manufacturing. With leaders like Raamps Industries, businesses can trust that every curve is crafted with accuracy, durability, and excellence in mind.

https://www.raampsindustries.com/services/cnc-bending/

Precision in Every Curve: How CNC Bending is Revolutionizing Metal Fabrication In the ever-evolving world of metal fabrication, precision and efficiency are no longer optional—they’re essential. Modern manufacturing demands tight tolerances, consistent results, and faster turnaround times. This is where CNC Bending Services have emerged as a game-changer, redefining how industries approach metal shaping and forming. What Is CNC Bending? CNC (Computer Numerical Control) Bending is a process that uses computer-controlled machines to bend sheet metal with extreme precision. Unlike manual bending, CNC technology allows for repeatable, error-free production, ensuring each part matches exact specifications. This technology is commonly used for materials like steel, aluminum, and stainless steel, producing components for automotive, construction, aerospace, and industrial applications. The Power of Precision in Metal CNC Bending Every angle, curve, and fold in a metal part affects the product’s overall quality and performance. Metal CNC Bending ensures unmatched accuracy by using advanced software to control the bending angles, pressure, and sequence. This reduces human error and material waste while maintaining consistent quality throughout production. For manufacturers, this precision translates to better fitting parts, reduced rework, and improved product durability—all while saving time and costs. Key Advantages of CNC Bending Services High Accuracy and Consistency CNC bending machines follow pre-programmed commands to deliver consistent results, no matter how complex the design. Efficiency and Speed Automated setups and quick tooling adjustments make CNC bending ideal for both small and large-volume production. Design Flexibility From simple angles to intricate shapes, CNC bending can handle diverse designs, allowing engineers more creative freedom. Cost-Effective Production With reduced labor requirements and minimal waste, CNC bending is one of the most economical methods for precision metal fabrication. Enhanced Durability The precise bending process ensures uniform stress distribution across the metal, improving the strength and longevity of components. Applications of Metal CNC Bending CNC bending plays a crucial role in producing components such as brackets, enclosures, frames, and panels used across various industries. Whether it’s the automotive sector needing structural parts or the construction industry requiring custom-fit panels, CNC bending provides the adaptability and precision modern projects demand. Why Choose Raamps Industries for CNC Bending Services? Raamps Industries stands at the forefront of CNC Bending Services, combining advanced technology with years of industry expertise. The company delivers tailored Metal CNC Bending solutions that meet strict client specifications while maintaining exceptional quality and turnaround speed. From prototype development to full-scale production, Raamps Industries ensures every curve, edge, and angle meets perfection. Conclusion The future of metal fabrication lies in precision, speed, and efficiency—and CNC Bending Services perfectly embody these principles. As industries continue to innovate and demand higher standards, Metal CNC Bending will remain a cornerstone of modern manufacturing. With leaders like Raamps Industries, businesses can trust that every curve is crafted with accuracy, durability, and excellence in mind. https://www.raampsindustries.com/services/cnc-bending/ WWW.RAAMPSINDUSTRIES.COMCNC Bending Services | Metal CNC Bending - RAAMPS IndustriesRAAMPS Industries provides precise CNC Bending Services for high-quality Metal CNC Bending, ensuring accuracy, efficiency, and superior fabrication results.0 Commenti 0 Condivisioni 3K VisualizzazioniEffettua l'accesso per mettere mi piace, condividere e commentare!

WWW.RAAMPSINDUSTRIES.COMCNC Bending Services | Metal CNC Bending - RAAMPS IndustriesRAAMPS Industries provides precise CNC Bending Services for high-quality Metal CNC Bending, ensuring accuracy, efficiency, and superior fabrication results.0 Commenti 0 Condivisioni 3K VisualizzazioniEffettua l'accesso per mettere mi piace, condividere e commentare! -

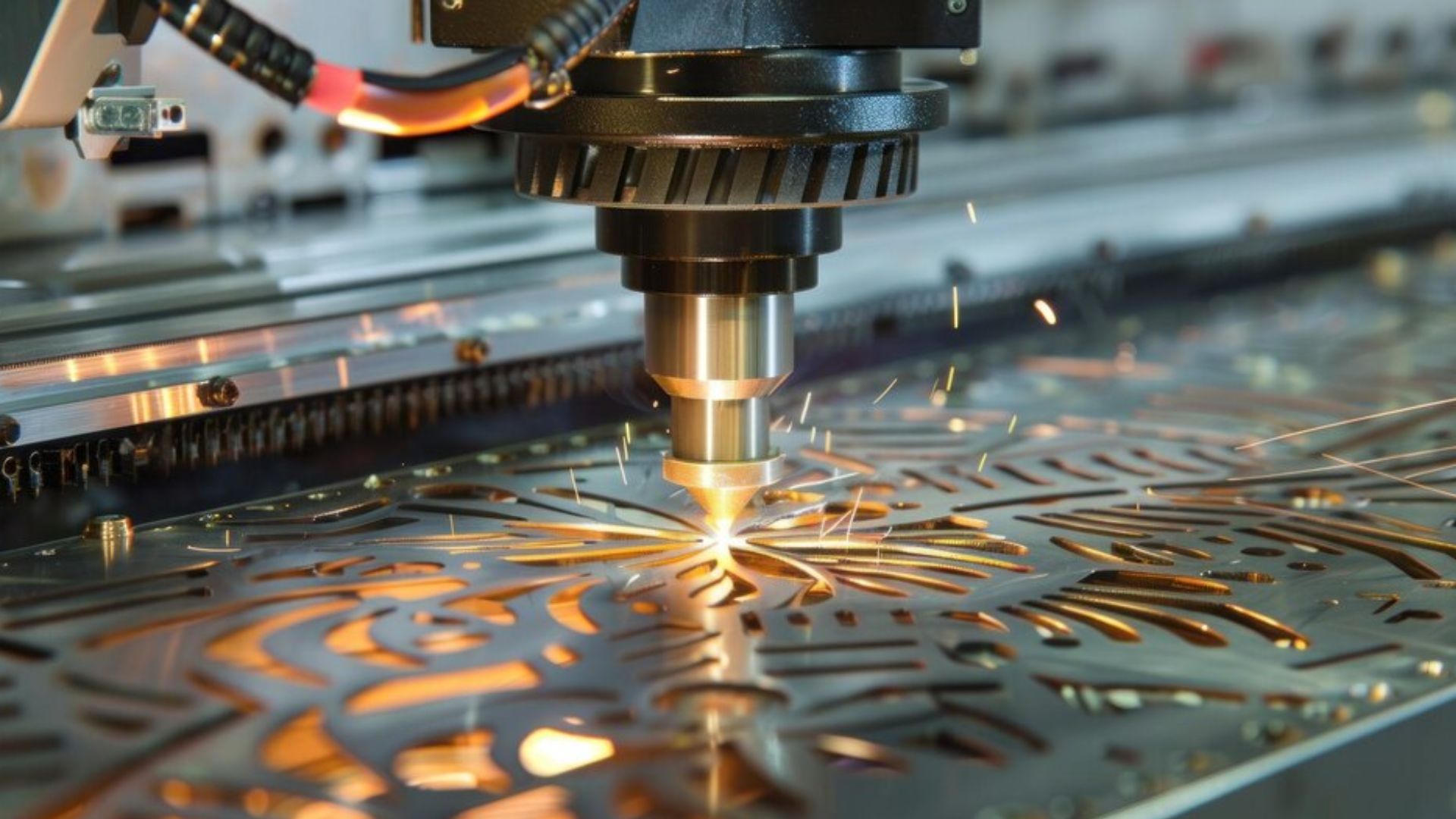

Top Benefits of Hiring a Professional Laser Cutting Service Provider

In the modern manufacturing and fabrication landscape, precision and efficiency are crucial. While many companies attempt to handle cutting in-house, partnering with a professional laser cutting service provider offers advantages that are hard to replicate internally. Laser cutting technology has transformed how industries approach design, prototyping, and production. Hiring an expert ensures you maximize the potential of this innovative technology.

1. Precision and Accuracy

Professional laser cutting services deliver unmatched precision. High-quality laser systems can cut intricate patterns and detailed shapes with minimal tolerances, ensuring that every piece meets exact specifications. This level of accuracy reduces errors, material wastage, and the need for rework.

2. Access to Advanced Technology

Professional providers invest in state-of-the-art laser cutting machinery that most businesses cannot afford to maintain in-house. These advanced systems can handle a wide range of materials—from metals and plastics to wood and acrylic—ensuring versatility for different projects.

3. Time and Cost Efficiency

Outsourcing laser cutting saves both time and money. Skilled service providers streamline the production process, reducing lead times and operational overhead. By minimizing waste and accelerating project timelines, businesses can focus on core activities while leaving the cutting to the experts.

4. Customization and Design Flexibility

Professional laser cutting services allow for complex designs and custom shapes that would be difficult with traditional cutting methods. This flexibility enables businesses to innovate, offer unique products, and meet specific client requirements without compromising quality.

5. Improved Safety and Risk Management

Laser cutting involves high-powered equipment that requires expertise to operate safely. Professional providers adhere to strict safety protocols, reducing the risk of workplace accidents and protecting your team from potential hazards.

6. Consistent Quality and Reliability

Partnering with a professional provider guarantees consistency across multiple production runs. Experienced technicians monitor every stage of the process, ensuring each cut is accurate and the finished products meet industry standards.

7. Focus on Core Business

Outsourcing laser cutting allows companies to focus on their core competencies—whether it’s product development, marketing, or sales—without diverting resources to manage complex cutting operations.

Raamps Industries: Your Trusted Laser Cutting Service Provider

When looking for reliable and professional laser cutting services, Raamps Industries stands out as a leading provider. With cutting-edge technology, skilled technicians, and a commitment to quality, Raamps Industries ensures precision, efficiency, and innovation across all projects. Their expertise spans multiple industries, delivering solutions that meet the highest standards.

Conclusion:

Hiring a professional laser cutting service provider offers precision, efficiency, flexibility, and safety that in-house operations often cannot match. Companies can reduce costs, improve production timelines, and focus on innovation by partnering with experts. Raamps Industries exemplifies these benefits, providing top-notch laser cutting services that drive quality and success in modern manufacturing.

Visit us - https://www.raampsindustries.com/services/laser-cutting/

Laser Cutting Services Provider

Top Benefits of Hiring a Professional Laser Cutting Service Provider In the modern manufacturing and fabrication landscape, precision and efficiency are crucial. While many companies attempt to handle cutting in-house, partnering with a professional laser cutting service provider offers advantages that are hard to replicate internally. Laser cutting technology has transformed how industries approach design, prototyping, and production. Hiring an expert ensures you maximize the potential of this innovative technology. 1. Precision and Accuracy Professional laser cutting services deliver unmatched precision. High-quality laser systems can cut intricate patterns and detailed shapes with minimal tolerances, ensuring that every piece meets exact specifications. This level of accuracy reduces errors, material wastage, and the need for rework. 2. Access to Advanced Technology Professional providers invest in state-of-the-art laser cutting machinery that most businesses cannot afford to maintain in-house. These advanced systems can handle a wide range of materials—from metals and plastics to wood and acrylic—ensuring versatility for different projects. 3. Time and Cost Efficiency Outsourcing laser cutting saves both time and money. Skilled service providers streamline the production process, reducing lead times and operational overhead. By minimizing waste and accelerating project timelines, businesses can focus on core activities while leaving the cutting to the experts. 4. Customization and Design Flexibility Professional laser cutting services allow for complex designs and custom shapes that would be difficult with traditional cutting methods. This flexibility enables businesses to innovate, offer unique products, and meet specific client requirements without compromising quality. 5. Improved Safety and Risk Management Laser cutting involves high-powered equipment that requires expertise to operate safely. Professional providers adhere to strict safety protocols, reducing the risk of workplace accidents and protecting your team from potential hazards. 6. Consistent Quality and Reliability Partnering with a professional provider guarantees consistency across multiple production runs. Experienced technicians monitor every stage of the process, ensuring each cut is accurate and the finished products meet industry standards. 7. Focus on Core Business Outsourcing laser cutting allows companies to focus on their core competencies—whether it’s product development, marketing, or sales—without diverting resources to manage complex cutting operations. Raamps Industries: Your Trusted Laser Cutting Service Provider When looking for reliable and professional laser cutting services, Raamps Industries stands out as a leading provider. With cutting-edge technology, skilled technicians, and a commitment to quality, Raamps Industries ensures precision, efficiency, and innovation across all projects. Their expertise spans multiple industries, delivering solutions that meet the highest standards. Conclusion: Hiring a professional laser cutting service provider offers precision, efficiency, flexibility, and safety that in-house operations often cannot match. Companies can reduce costs, improve production timelines, and focus on innovation by partnering with experts. Raamps Industries exemplifies these benefits, providing top-notch laser cutting services that drive quality and success in modern manufacturing. Visit us - https://www.raampsindustries.com/services/laser-cutting/ Laser Cutting Services Provider WWW.RAAMPSINDUSTRIES.COMLaser Cutting Services | Sheet Metal Cutting - RAAMPS IndustriesRAAMPS Industries, a leading Laser Cutting Services Provider, offers precision Sheet Metal Laser Cutting solutions for high-quality and efficient manufacturing.0 Commenti 0 Condivisioni 3K Visualizzazioni

WWW.RAAMPSINDUSTRIES.COMLaser Cutting Services | Sheet Metal Cutting - RAAMPS IndustriesRAAMPS Industries, a leading Laser Cutting Services Provider, offers precision Sheet Metal Laser Cutting solutions for high-quality and efficient manufacturing.0 Commenti 0 Condivisioni 3K Visualizzazioni

Altre storie