EIL Registered Manufacturers: Ensuring Quality and Reliability in Industrial Solutions

When it comes to large-scale industrial projects in sectors like oil & gas, petrochemicals, fertilizers, and refineries, quality and compliance are non-negotiable. One of the most trusted certifications in India for manufacturers is registration with Engineers India Limited (EIL). Being listed as EIL registered manufacturers is a mark of excellence, reliability, and adherence to stringent industry standards.

At Gas Processing, we take pride in being recognized among the trusted EIL registered manufacturers, delivering top-quality equipment and solutions that meet the highest levels of safety and performance.

What Does It Mean to Be an EIL Registered Manufacturer?

EIL, a leading engineering consultancy and EPC company in India, has a robust vendor registration process. Manufacturers who are registered with EIL undergo thorough technical evaluations, quality checks, and audits to ensure their products comply with industry norms.

By working with EIL registered manufacturers, clients can be assured of:

Compliance with international quality standards

Reliable performance in critical operations

Safety-tested and durable equipment

Hassle-free approval in EIL-supervised projects

Why Choose Gas Processing as Your EIL Registered Manufacturer?

At Gas Processing, we are committed to engineering excellence and customer satisfaction. Our status as EIL registered manufacturers ensures that every product we deliver meets rigorous quality requirements. From design to fabrication and testing, our processes align with EIL’s specifications.

We specialize in:

Process equipment for oil & gas industries

Pressure vessels and filter vessels

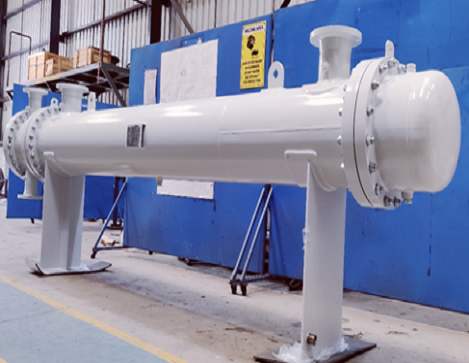

Heat exchangers and PSA systems

Biogas and renewable energy solutions

Our products are built with precision, keeping in mind the operational challenges of industries where downtime is not an option.

Benefits of Partnering with Gas Processing

Assured Quality & Certification – Every unit undergoes stringent testing before dispatch.

EIL Approval Advantage – Ensures smooth acceptance in EIL-monitored projects.

Customization – Tailor-made solutions as per client specifications.

Experience & Expertise – Years of serving industries with reliable engineering solutions.

Conclusion

Choosing an EIL registered manufacturer means choosing reliability, trust, and long-term value. At Gas Processing, we are proud to deliver world-class solutions that are not only compliant but also innovative and cost-effective.

If you are looking for a trusted partner in the field of industrial equipment manufacturing, Gas Processing is here to meet your needs with quality, efficiency, and commitment.

Visit us https://gasprocessing.in/processing-equipment/

When it comes to large-scale industrial projects in sectors like oil & gas, petrochemicals, fertilizers, and refineries, quality and compliance are non-negotiable. One of the most trusted certifications in India for manufacturers is registration with Engineers India Limited (EIL). Being listed as EIL registered manufacturers is a mark of excellence, reliability, and adherence to stringent industry standards.

At Gas Processing, we take pride in being recognized among the trusted EIL registered manufacturers, delivering top-quality equipment and solutions that meet the highest levels of safety and performance.

What Does It Mean to Be an EIL Registered Manufacturer?

EIL, a leading engineering consultancy and EPC company in India, has a robust vendor registration process. Manufacturers who are registered with EIL undergo thorough technical evaluations, quality checks, and audits to ensure their products comply with industry norms.

By working with EIL registered manufacturers, clients can be assured of:

Compliance with international quality standards

Reliable performance in critical operations

Safety-tested and durable equipment

Hassle-free approval in EIL-supervised projects

Why Choose Gas Processing as Your EIL Registered Manufacturer?

At Gas Processing, we are committed to engineering excellence and customer satisfaction. Our status as EIL registered manufacturers ensures that every product we deliver meets rigorous quality requirements. From design to fabrication and testing, our processes align with EIL’s specifications.

We specialize in:

Process equipment for oil & gas industries

Pressure vessels and filter vessels

Heat exchangers and PSA systems

Biogas and renewable energy solutions

Our products are built with precision, keeping in mind the operational challenges of industries where downtime is not an option.

Benefits of Partnering with Gas Processing

Assured Quality & Certification – Every unit undergoes stringent testing before dispatch.

EIL Approval Advantage – Ensures smooth acceptance in EIL-monitored projects.

Customization – Tailor-made solutions as per client specifications.

Experience & Expertise – Years of serving industries with reliable engineering solutions.

Conclusion

Choosing an EIL registered manufacturer means choosing reliability, trust, and long-term value. At Gas Processing, we are proud to deliver world-class solutions that are not only compliant but also innovative and cost-effective.

If you are looking for a trusted partner in the field of industrial equipment manufacturing, Gas Processing is here to meet your needs with quality, efficiency, and commitment.

Visit us https://gasprocessing.in/processing-equipment/

EIL Registered Manufacturers: Ensuring Quality and Reliability in Industrial Solutions

When it comes to large-scale industrial projects in sectors like oil & gas, petrochemicals, fertilizers, and refineries, quality and compliance are non-negotiable. One of the most trusted certifications in India for manufacturers is registration with Engineers India Limited (EIL). Being listed as EIL registered manufacturers is a mark of excellence, reliability, and adherence to stringent industry standards.

At Gas Processing, we take pride in being recognized among the trusted EIL registered manufacturers, delivering top-quality equipment and solutions that meet the highest levels of safety and performance.

What Does It Mean to Be an EIL Registered Manufacturer?

EIL, a leading engineering consultancy and EPC company in India, has a robust vendor registration process. Manufacturers who are registered with EIL undergo thorough technical evaluations, quality checks, and audits to ensure their products comply with industry norms.

By working with EIL registered manufacturers, clients can be assured of:

✅ Compliance with international quality standards

✅ Reliable performance in critical operations

✅ Safety-tested and durable equipment

✅ Hassle-free approval in EIL-supervised projects

Why Choose Gas Processing as Your EIL Registered Manufacturer?

At Gas Processing, we are committed to engineering excellence and customer satisfaction. Our status as EIL registered manufacturers ensures that every product we deliver meets rigorous quality requirements. From design to fabrication and testing, our processes align with EIL’s specifications.

We specialize in:

Process equipment for oil & gas industries

Pressure vessels and filter vessels

Heat exchangers and PSA systems

Biogas and renewable energy solutions

Our products are built with precision, keeping in mind the operational challenges of industries where downtime is not an option.

Benefits of Partnering with Gas Processing

Assured Quality & Certification – Every unit undergoes stringent testing before dispatch.

EIL Approval Advantage – Ensures smooth acceptance in EIL-monitored projects.

Customization – Tailor-made solutions as per client specifications.

Experience & Expertise – Years of serving industries with reliable engineering solutions.

Conclusion

Choosing an EIL registered manufacturer means choosing reliability, trust, and long-term value. At Gas Processing, we are proud to deliver world-class solutions that are not only compliant but also innovative and cost-effective.

If you are looking for a trusted partner in the field of industrial equipment manufacturing, Gas Processing is here to meet your needs with quality, efficiency, and commitment.

Visit us https://gasprocessing.in/processing-equipment/

0 Commentarii

0 Distribuiri

2K Views